D is for Distraction update (#61)

* Fix for Home page and future features page added * Update Acceleration_Compensation.md * Update Fuel_Overview.md * More fuel info * More X-tau * Ongoing Tasks list Free for all list for people to update as they change track * Update Ongoing_Tasks * Hidden names on pages and multi-spark page * Update X-tau_Wall_Wetting.md * Update * Update AlphaN.md * Update Speed_Density.md * Fuel control overview improvement, added wide band page * Update Wide_Band_Sensors.md * Update Fuel_Overview.md * Update MAF.md * Update MAF.md * Update rusEFI_console_directory.png * Delete rusEFI_console_directory.png * Delete wall_wetting.md * Fuel Index + Formats Also old wall wetting page kill * Update Pages_Fuel.md * Update Pages_Fuel.md * Create Pages_Hardware.md * Update Pages_Hardware.md * Sensor and Actuators index * Start of Ignition Index * Create Fuel_Injectors.md * Moved file * Added PNP72 jumper info * More updates + Software pages * Update MREAdapter72.md * Create Roadmap_Fuel.md * Created Kit Instruction link * Dev_Hardware_Guidelines * Images and links update * Update Dev_Hardware_Guidelines.md * Update Dev_Hardware_Guidelines.md * Update .gitignore * Ignition FAQ and start of what we cannot do * found by **Serching the forum** update * Searching at top of side bar * Minor grammar/wording edits. * MRE * Minor grammar/wording edits. * Minor spacing/readability edit. * Minor grammar/wording edits. * Minor spacing/readability edit. * Minor grammar/wording edits. * Minor grammar/wording edits. * 48 * Minor grammar/wording edits. * Minor grammar/wording edits. * Updated Deucalion_uart (markdown) * Minor spacing/readability edit. * Photo fixes * Minor grammar/wording edits. * Updated Dev_Hardware_Guidelines (markdown) * Minor grammar/wording edits. * Minor grammar/wording edits. * Updated Documentation_Workflow (markdown) * Updated Documentation_Workflow (markdown) * Minor spacing/readability edit. * Create Vault_Of_Ignition_Parts.md * Update Pages_Ignition.md * Minor spacing/readability edit. * Updated FAQ Basic Wiring and Connections (markdown) * Minor grammar/wording edits. * Minor grammar/wording edits. * Minor spacing/readability edit. * Minor spacing/readability edit. * Updated Frankenso (markdown) * Update FAQ_Ignition.md * Minor grammar/wording edits. * Minor grammar/wording edits. * Minor grammar/wording edits. * D is for DISTRACTION * Updated Feature Requests: Feature Bounty Program (markdown) * Updated Feature Requests Feature Bounty Program (markdown) Co-authored-by: Glitch Knitter <64521139+GlitchKnitter@users.noreply.github.com> Co-authored-by: rusefi <rusefillc@gmail.com>

This commit is contained in:

parent

4a1db2ae42

commit

004946a858

|

|

@ -2,12 +2,15 @@

|

|||

See also [Trigger](Trigger)

|

||||

|

||||

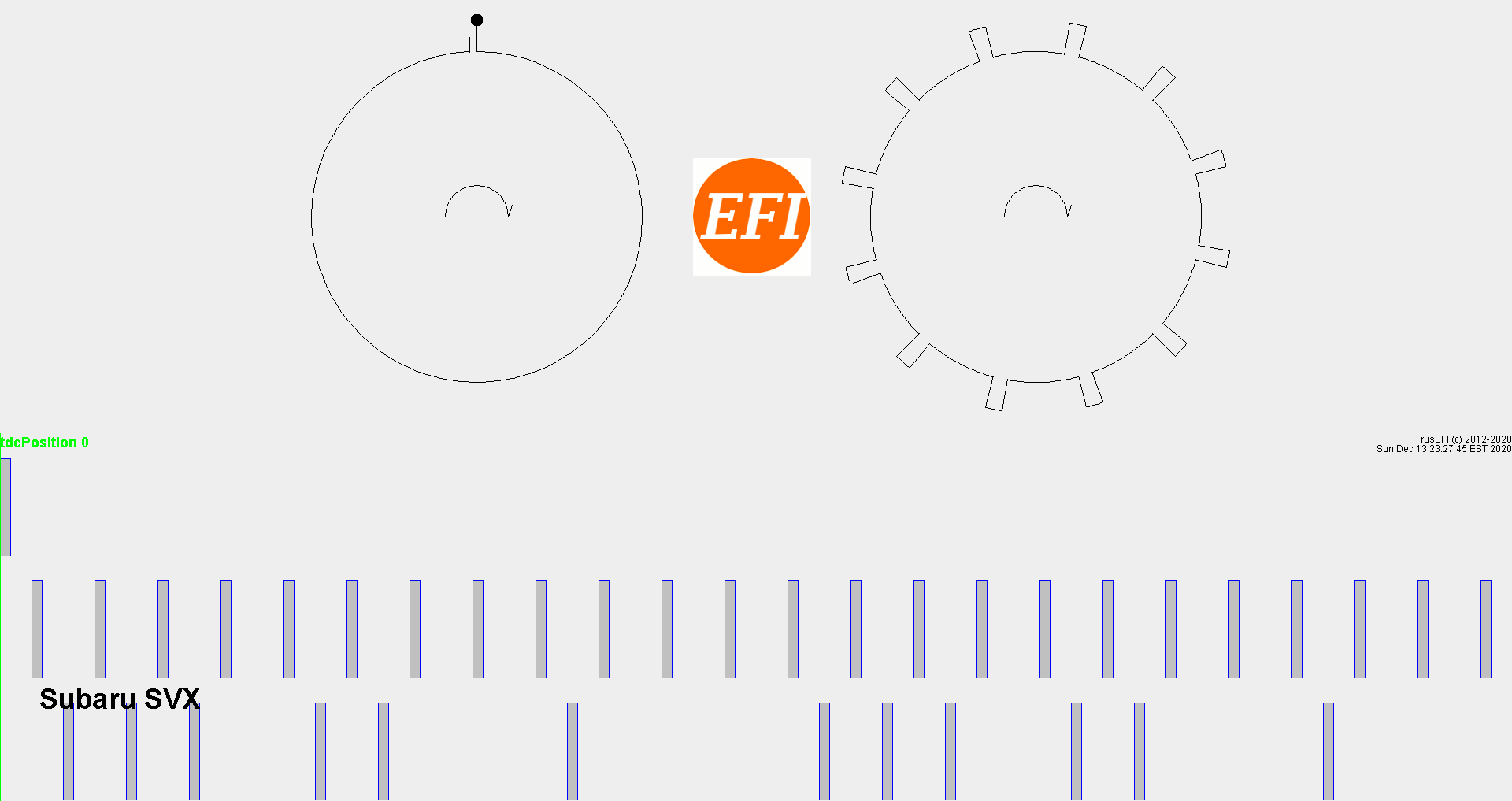

May, 2020: Subaru SVX added

|

||||

|

||||

|

||||

|

||||

|

||||

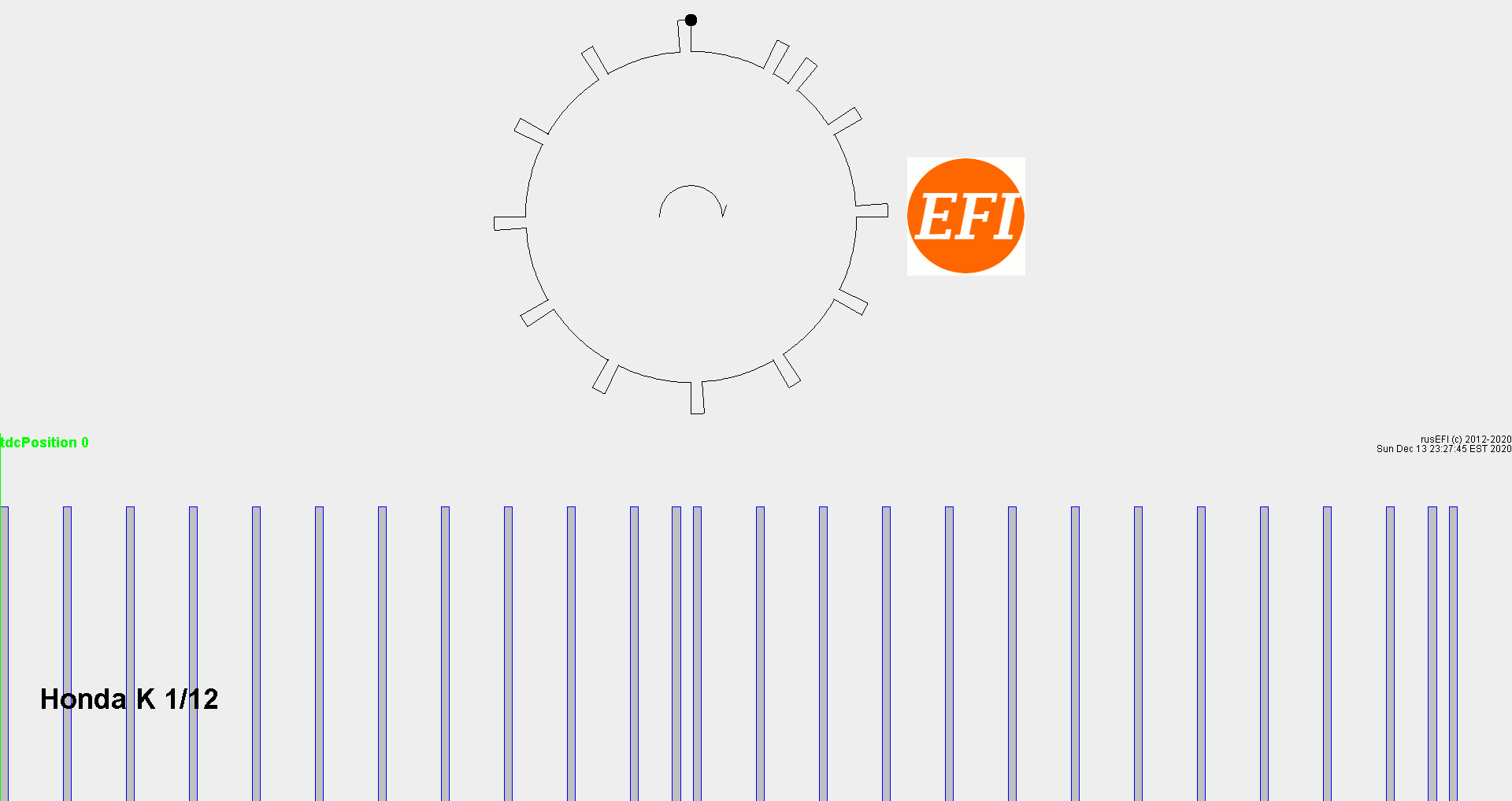

April, 2020: Honda K 12+1 added.

|

||||

|

||||

|

||||

|

||||

|

||||

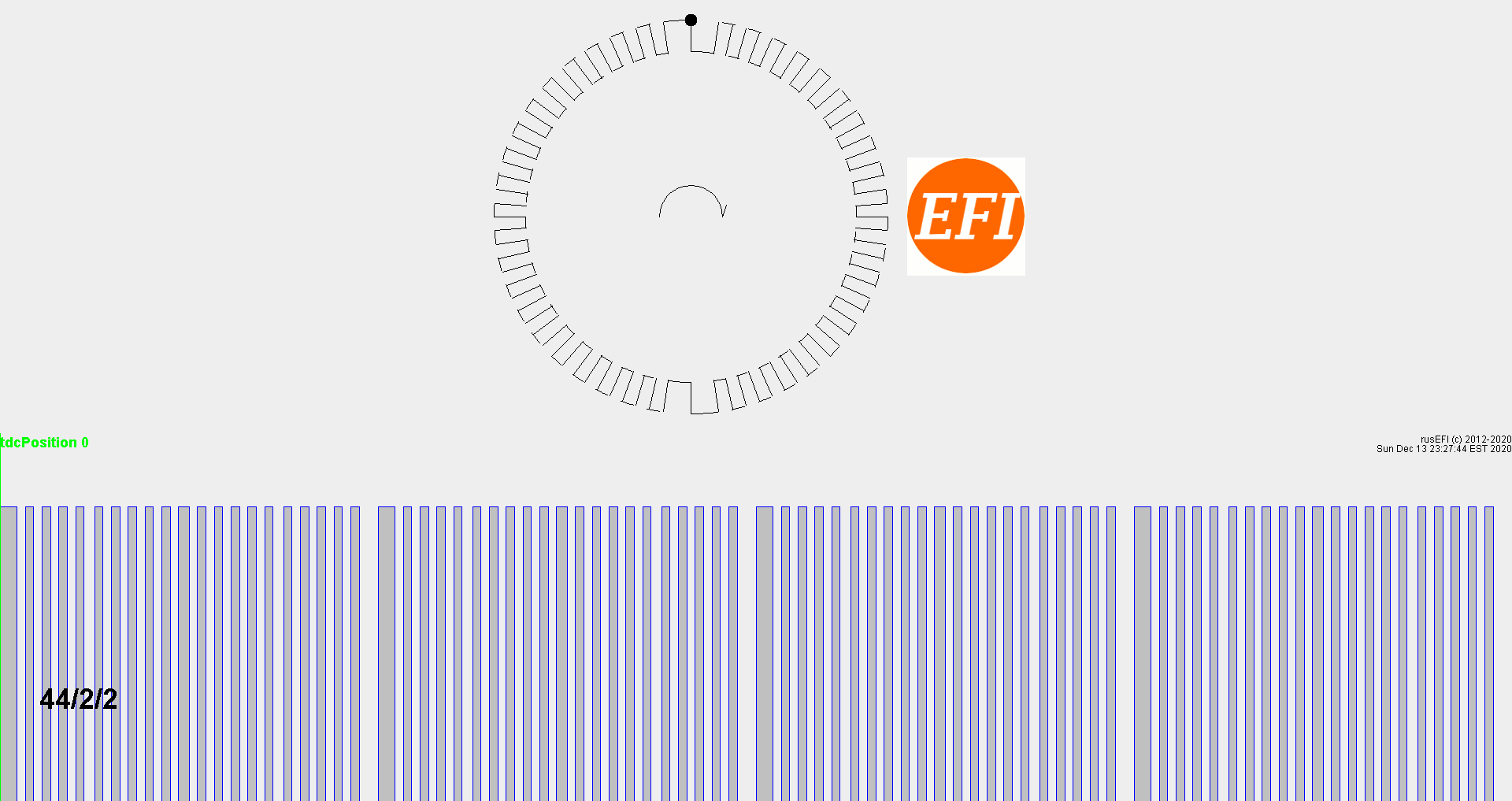

April, 2020: Renix 44-2-2 added.

|

||||

|

||||

|

||||

|

|

@ -1,7 +1,7 @@

|

|||

Reduce visibility where possible

|

||||

* Reduce visibility where possible

|

||||

|

||||

avoid magic constants

|

||||

* Avoid magic constants

|

||||

|

||||

please do not push dead code

|

||||

* Please do not push dead code

|

||||

|

||||

See https://rusefi.com/wiki/index.php?title=Development:Code_Style

|

||||

See here: https://rusefi.com/wiki/index.php?title=Development:Code_Style

|

||||

|

|

@ -1,7 +1,7 @@

|

|||

|

||||

# What is Cranking?

|

||||

|

||||

In order to get an engine running, it first needs to be rotated at sufficient speed. Thus, it gets the fuel pumped up to the cylinders and ignited and enables the engine to run on its own power. Cranking the engine simply means turning the engine's crankshaft that rotates the engine to power itself.

|

||||

In order to get an engine running, it first needs to be rotated at sufficient speed. This gets the fuel pumped up to the cylinders and ignited and enables the engine to run on its own power. Cranking the engine simply means turning the engine's crankshaft that rotates the engine to power itself.

|

||||

|

||||

|

||||

<!-- This would be rendered as a collapsable section. from 'details' to closing 'details' -->

|

||||

|

|

@ -25,7 +25,7 @@ Cranking mode is defined as any RPM value below the 'cranking RPM' setting. Duri

|

|||

|

||||

<!-- this magic '>' make a one line quote block -->

|

||||

|

||||

> <img src="FAQ/icons/hint.png" style="vertical-align:middle"> *Hint: If you have a fresh new engine ready for cranking, and you want to prepare the configuration for the first start, Please first see: [First Engine Start](First_engine_start).*

|

||||

> <img src="FAQ/icons/hint.png" style="vertical-align:middle"> *Hint: If you have a fresh new engine ready for cranking, and you want to prepare the configuration for the first start, please first see: [First Engine Start](First_engine_start).*

|

||||

|

||||

|

||||

# Cranking Settings

|

||||

|

|

@ -99,7 +99,7 @@ rusEFI Console command:

|

|||

|

||||

### Falloff temperature

|

||||

|

||||

*This sets the temperature above which no priming pulse is used, The value at -40 is reduced until there is no more priming injection at this temperature.*

|

||||

*This sets the temperature above which no priming pulse is used. The value at -40 is reduced until there is no more priming injection at this temperature.*

|

||||

|

||||

## Fuel Settings

|

||||

### Injection mode

|

||||

|

|

@ -138,7 +138,7 @@ To adjust cranking fuel, use ```set cranking_fuel XXX``` command, where XXX is t

|

|||

|

||||

### Use separate Advance Table for cranking

|

||||

|

||||

*This activates a separate advance table for cranking conditions, this allows cranking advance to be RPM dependant.*

|

||||

*This activates a separate advance table for cranking conditions, which allows the cranking advance to be RPM dependant.*

|

||||

|

||||

|

||||

|

||||

|

|

@ -153,10 +153,10 @@ To adjust cranking fuel, use ```set cranking_fuel XXX``` command, where XXX is t

|

|||

|

||||

## IAC Settings

|

||||

### Cranking IAC position

|

||||

*This is the IAC position during cranking, some engines start better if given more air during cranking to improve cylinder filling.*

|

||||

*This is the IAC position during cranking; some engines start better if given more air during cranking to improve cylinder filling.*

|

||||

|

||||

### After cranking IAC taper duration

|

||||

*This is the duration in cycles that the IAC will take to reach its normal idle position, it can be used to hold the idle higher for a few seconds after cranking to improve startup.*

|

||||

*This is the duration in cycles that the IAC will take to reach its normal idle position; it can be used to hold the idle higher for a few seconds after cranking to improve startup.*

|

||||

|

||||

### Override IAC multiplier for cranking

|

||||

*This setting overrides the normal multiplication values that have been set for the idle air control valve during cranking. If this setting is enabled the "IAC multiplier" table in the Cranking settings tab needs to be adjusted appropriately or potentially no IAC opening will occur.*

|

||||

|

|

@ -173,10 +173,9 @@ To adjust cranking fuel, use ```set cranking_fuel XXX``` command, where XXX is t

|

|||

During cranking, two curves control the amount of fuel injected:

|

||||

"cranking coolant temperature multiplier" and "cranking duration multiplier".

|

||||

|

||||

A Cold engine usually requires more cranking fuel, cranking fuel usually tapers down during cranking since more fuel is needed in the beginning and not really needed later.

|

||||

A Cold engine usually requires more cranking fuel; cranking fuel usually tapers down during cranking since more fuel is needed in the beginning and not really needed later.

|

||||

|

||||

If you have flooded your engine, i.e. got too much fuel on your spark plugs, "Cylinder Cleanup" is recommenced - i.e. cranking with wide-open throttle without any fuel squired into the cylinders

|

||||

in order to ventilate your cylinders.

|

||||

If you have flooded your engine, i.e. got too much fuel on your spark plugs, "Cylinder Cleanup" is recommenced - i.e. cranking with wide-open throttle without any fuel squirted into the cylinders in order to ventilate your cylinders.

|

||||

|

||||

As of April 2019 "base fuel pulse" is deprecated, "1" is recommended.

|

||||

|

||||

|

|

@ -0,0 +1,15 @@

|

|||

# D is for... **DISTRACTION**

|

||||

|

||||

One of the major things rusEFI struggles with is the developers and contributors getting sidetracked by interesting shiny things.

|

||||

When this happens we can loose a Dev for several days while he plays with a quantum capacitor or tries to implement crypto mining on the spare CPU cycles.

|

||||

|

||||

While in essence this is not a bad thing, it does mean that progress slows right down. With enough distraction then progress grinds to a halt.

|

||||

|

||||

It is due to these distractions (and the fact that some times out Devs also have lives!) that rusEFI has a lot of features that are partially implemented and require further work to finish them off.

|

||||

|

||||

What this means is we politely request that people try not to ask easily answered questions to the Devs and keep feature requests to a minimum for now.

|

||||

|

||||

There are details of our plans for fuel strategy improvements [at this link](Roadmap_Fuel) as well as a comprehensive list of existing features and ones that are in development [here](Dev_Status)

|

||||

If your idea does not already appear there then consider making a Github ticket but please have a think if that feature would really add to rusEFI and if it needs to be done ASAP. If not then please tag the ticket as a future feature and low priority.

|

||||

|

||||

Most simple questions can be answered by [searching the wiki](HOWTO-Search-on-rusEFI-wiki) or by [searching the forum](https://rusefi.com/forum/search.php)

|

||||

|

|

@ -1,6 +1,6 @@

|

|||

Debug fields is an advanced troubleshooting feature allowing one to monitor internal state of some rusEfi subsystems.

|

||||

Debug fields is an advanced troubleshooting feature allowing one to monitor the internal state of some rusEfi subsystems.

|

||||

|

||||

In TunerStudio, select "Base Engine Settings -> Debug Mode" and use gauges from "Debug" category.

|

||||

In TunerStudio, select "Base Engine Settings -> Debug Mode" and use the gauges from "Debug" category.

|

||||

|

||||

|

||||

See https://rusefi.com/wiki/index.php?title=Manual:Debug_fields

|

||||

|

|

@ -7,28 +7,28 @@ suggestions on how to design and work with things like a PCB layout.

|

|||

---

|

||||

|

||||

## General suggested environment

|

||||

- Allows an ambient temperature from -40C to +85C (-40F to 185F) AEC Q100 Grade 3

|

||||

- Allow an ambient temperature from -40C to +85C (-40F to 185F) AEC Q100 Grade 3

|

||||

- Voltage regulators that are compatible with ISO 7637-2 and ISO16750-2 (100V repetitive pulses via 50ohm impedance, 18 V for 60 min, 24V for 60s to all relevant inputs, withstand a reversed voltage for 60s, 500V rms (50 Hz to 60 Hz) for 60s, ect).

|

||||

- Voltage regulators that follow Maxim's suggestions here (cold cranking down to 4V for up to 40mS)

|

||||

- Reverse polarity protection as noted in this video (P-MOSFET style)

|

||||

- Humidity allowed up to 100% (water resistant enclosure, perhaps fully potted)

|

||||

- Sensor inputs are capable of human body model ESD (100 pF 1.5 kohm 500V to 1kV class 1B or better)

|

||||

- All sensor inputs can survive a sustained short to 12V or GND. (fused as required)

|

||||

- All sensor inputs should float either full scale or min scale when a wire is not connected. The normal operation of the sensor should not hit the full scale or min scale. This allows full or min scale to be an error indicator.

|

||||

- All sensor GND references are fuse protected such a dead short to 12V can be repaired, with out replacing the entire PCB.

|

||||

- Should be able to maintain crank angle accuracy of .2 degrees up to at least 6kRPM. When above .2 degree tolerance, it should be noted some where such that tuning people know when there might be a tolerance issue.

|

||||

- All sensor inputs should float either full scale or min scale when a wire is not connected. The normal operation of the sensor should not hit the full scale or min scale. This allows for full or min scale to be an error indicator.

|

||||

- All sensor GND references fuse protected by such a dead short to 12V can be repaired, without replacing the entire PCB.

|

||||

- Should be able to maintain crank angle accuracy of .2 degrees up to at least 6kRPM. When above .2 degree tolerance, it should be noted somewhere so that tuning people know when there might be a tolerance issue.

|

||||

- Native ignition drivers should be min 400V, 20A, and 300mJ SCIS energy. Higher rating for any of these parameters is better.

|

||||

- When high side drive is provided with the ability to provide more than 20mA, current sensing and limiting should be implemented to prevent the possibility of electrical fire. See VND5E025AK for an example of a chip that has this feature.

|

||||

- Take AEC Q100 into consideration See freely published documents found [here](http://www.aecouncil.com/AECDocuments.html)

|

||||

- Take AEC Q100 into consideration. See freely published documents found [here](http://www.aecouncil.com/AECDocuments.html)

|

||||

|

||||

---

|

||||

|

||||

## Connectors

|

||||

- Connectors should be keyed such that it is difficult to accidentally swap connectors

|

||||

- Connectors should be able to carry the max possible load with one pin, no doubling up pins to get increased current ratings. It is OK to double up pins to decrease connector resistance for a lower voltage drop.

|

||||

- Connectors should be able to carry the max possible load with one pin, ensuring no doubling up pins to get increased current ratings. It is OK to double up pins to decrease connector resistance for a lower voltage drop.

|

||||

- Connectors should survive the currents passed when inputs are shorted to GND or 12V as noted above in the suggested environment.

|

||||

- GND(s) should be properly sized such that 99% duty on the fuel injectors will not raise the GND voltage and prevent the MOSFET's from operating correctly.

|

||||

- Suggested to use twisted pair PVC wire as a minimum for signal wires, silicon jackets are more costly, but also much better.

|

||||

- Suggested to use twisted pair PVC wire as a minimum for signal wires; silicon jackets are more costly, but also much better.

|

||||

- Suggested to use the "Tin Commandments" found here

|

||||

|

||||

---

|

||||

|

|

@ -45,9 +45,9 @@ http://rusefi.com/wiki/index.php?title=Manual:Hardware_Frankenso_board

|

|||

|

||||

#### - Brain board

|

||||

|

||||

The brain board can be the off the shelf STMDiscoveryF4. However the Discovery has several circuits like the analog microphone circuits which change how a particular pin is loaded. We have noticed that this pin loading cause the injector circuits to vary pulse widths. Because of this we have developed a stripped down version of the discovery board with out the extra circuits. Both boards have the same general specifications, same clock rates, same IO headers with the same pin out's, ect.

|

||||

The brain board can be the off the shelf STMDiscoveryF4. However the Discovery has several circuits like the analog microphone circuits which change how a particular pin is loaded. We have noticed that this pin loading cause the injector circuits to vary pulse widths. Because of this we have developed a stripped down version of the Discovery board without the extra circuits. Both boards have the same general specifications, same clock rates, same IO headers with the same pin outs, ect.

|

||||

|

||||

Forum thread about this PCB found [here](http://rusefi.com/forum/viewtopic.php?f=4&t=381)

|

||||

Forum thread about this PCB found [here](http://rusefi.com/forum/viewtopic.php?f=4&t=381), also see:

|

||||

[Current pin out](https://docs.google.com/spreadsheet/ccc?key=0Arl1FeMZcfisdGpIZVBGMWFIQXdycnVNOWRjRG5YNnc)

|

||||

|

||||

|

||||

|

|

@ -95,12 +95,12 @@ http://rusefi.com/wiki/index.php?title=Manual:Hardware:CAN_sniffer

|

|||

|

||||

[176122-6 ECU connector board](http://rusefi.com/forum/viewtopic.php?f=4&t=507)

|

||||

|

||||

[our first ECU connector breakout board](http://rusefi.com/forum/viewtopic.php?f=4&t=3)

|

||||

[Our first ECU connector breakout board](http://rusefi.com/forum/viewtopic.php?f=4&t=3)

|

||||

|

||||

[migration breakout board includes fused jumpers to move wires](http://rusefi.com/forum/viewtopic.php?f=4&t=454)

|

||||

[Migration breakout board includes fused jumpers to move wires](http://rusefi.com/forum/viewtopic.php?f=4&t=454)

|

||||

|

||||

[Ignition modules A couple ignition (igniter) modules found in this thread.](https://rusefi.com//forum/viewtopic.php?f=4&t=286)

|

||||

|

||||

[2003 dodge Neon test mule](https://rusefi.com/forum/viewtopic.php?f=3&t=696)

|

||||

|

||||

[connector boards](https://rusefi.com/wiki/index.php?title=Hardware:OEM_connectors)

|

||||

[Connector boards](https://rusefi.com/wiki/index.php?title=Hardware:OEM_connectors)

|

||||

|

|

@ -1,17 +1,17 @@

|

|||

As of April, 2020 the strategy is to move from MediaWiki https://rusefi.com/wiki/ to

|

||||

https://github.com/rusefi/rusefi/wiki/

|

||||

|

||||

Full list of (Legacy) mediawiki pages is available at https://rusefi.com/wiki/index.php?title=Special:AllPages

|

||||

A full list of (Legacy) mediawiki pages is available at https://rusefi.com/wiki/index.php?title=Special:AllPages

|

||||

|

||||

|

||||

Arguments for github:

|

||||

1) access control

|

||||

1) better change review process

|

||||

1) better history and version control management

|

||||

1) Access control

|

||||

2) Better change review process

|

||||

3) Better history and version control management

|

||||

|

||||

Arguments against github

|

||||

1) Weird workflow with two separate git repositories

|

||||

1) Weird inconsistency of markup language between two git repositories

|

||||

2) Weird inconsistency of markup language between two git repositories

|

||||

|

||||

Arguments for mediawiki:

|

||||

1) ?

|

||||

|

|

|

|||

|

|

@ -2,40 +2,36 @@ In order to leverage github/wiki look&feel in combination with github pull reque

|

|||

|

||||

1) Technical git repository https://github.com/rusefi/rusefi_documentation is used to submit content using fork&pull request process

|

||||

|

||||

2) user-facing https://github.com/rusefi/rusefi.wiki.git repository is displayed to viewers at https://github.com/rusefi/rusefi/wiki

|

||||

Jenkins automation merges all changes from technical git into https://github.com/rusefi/rusefi.wiki.git behind the scenes.

|

||||

2) The user-facing https://github.com/rusefi/rusefi.wiki.git repository is displayed to viewers at https://github.com/rusefi/rusefi/wiki and Jenkins automation merges all changes from technical git into https://github.com/rusefi/rusefi.wiki.git behind the scenes.

|

||||

|

||||

|

||||

For example, in order for user abelom to edit this page:

|

||||

|

||||

1) abelom would start editing at https://github.com/rusefi/rusefi_documentation/blob/master/Documentation_Workflow.md which would automatically create a branch in https://github.com/abelom/rusefi_documentation fork

|

||||

1) once changed are made, abelom would create a Pull Request

|

||||

3) once that PR is merged into primary rusEfi modified content would appear as https://github.com/rusefi/rusefi_documentation/blob/master/Documentation_Workflow.md

|

||||

4) within the next 5 minutes automation would sync this page into wiki git and it would be available with nicer layout as https://github.com/rusefi/rusefi/wiki/Documentation_Workflow

|

||||

2) Once changed are made, abelom would create a Pull Request

|

||||

3) Once that PR is merged into primary rusEfi modified content would appear as https://github.com/rusefi/rusefi_documentation/blob/master/Documentation_Workflow.md

|

||||

4) Within the next 5 minutes automation would sync this page into wiki git and it would be available with nicer layout as https://github.com/rusefi/rusefi/wiki/Documentation_Workflow

|

||||

|

||||

Same but in different terms:

|

||||

|

||||

1) fork https://github.com/rusefi/rusefi_documentation

|

||||

2) make your changes

|

||||

3) PR you changes

|

||||

4) once PR is merged by one of moderators, your changes would appear at https://github.com/rusefi/rusefi_documentation instantaneously

|

||||

5) within the next 5 minutes magic happens and changes appear at https://github.com/rusefi/rusefi/wiki

|

||||

1) Fork https://github.com/rusefi/rusefi_documentation

|

||||

2) Make your changes

|

||||

3) PR your changes

|

||||

4) Once PR is merged by one of moderators, your changes will appear at https://github.com/rusefi/rusefi_documentation instantaneously

|

||||

5) Within the next 5 minutes magic happens and the changes appear at https://github.com/rusefi/rusefi/wiki

|

||||

|

||||

|

||||

Q: Is there a place where we are holding all images for these documents?

|

||||

|

||||

A: We have images in the same repository! Just add your images while editing pages. Please consider using some (any really) folder structure.

|

||||

**Q:** Is there a place where we are holding all images for these documents?

|

||||

**A:** We have images in the same repository! Just add your images while editing pages. Please consider using some (any really) folder structure.

|

||||

|

||||

For example https://github.com/rusefi/rusefi_documentation/blob/master/FAQ/images/TunerStudio_new_project.png is visible on /wiki/ as https://raw.githubusercontent.com/wiki/rusefi/rusefi/FAQ/images/TunerStudio_new_project.png

|

||||

|

||||

Long story short, for images to work good both in technical git and user-facing wiki, we place all .md files into the same root folder.

|

||||

Long story short, for images to work correctly both in the technical git and the user-facing wiki, we place all .md files into the same root folder.

|

||||

|

||||

(More deteils:

|

||||

Please note that all .md files like https://github.com/rusefi/rusefi_documentation/blob/master/FAQ/HOWTO_quick_start.md are displayed without folder name like https://github.com/rusefi/rusefi/wiki/HOWTO_quick_start which also means

|

||||

that you need full image path like ``FAQ/images/rusEfi_console/rusEfi_console_start_screen.png`` for image to be rendered properly. This is one of github wiki features which are a bit counter-intuitive to me.

|

||||

(More details:

|

||||

Please note that all .md files like https://github.com/rusefi/rusefi_documentation/blob/master/FAQ/HOWTO_quick_start.md are displayed without folder name like https://github.com/rusefi/rusefi/wiki/HOWTO_quick_start - which also means

|

||||

that you need full image path like ``FAQ/images/rusEfi_console/rusEfi_console_start_screen.png`` for the image to be rendered properly. This is one of the github wiki features which are a bit counter-intuitive to me.

|

||||

|

||||

This also means that .md file names have to be unique for the whole.)

|

||||

|

||||

Q: what fancy options do we have?

|

||||

|

||||

A: we can do collapsable sections & hints sections! see [cranking](cranking)

|

||||

**Q:** What sort of fancy options do we have?

|

||||

**A:** We can do collapsible sections & hints sections! See [cranking](cranking) for an example.

|

||||

|

|

@ -1,34 +1,41 @@

|

|||

# Intro

|

||||

|

||||

This page is going to have information about how to hook up to rusEFI hardware, in general. It's not intended to be a guide to a specific hardware variant but rather how to figure out what you're going to need to run different kinds of hardware you'd find in an engine bay. ***WARNING: The exact implementation of these pins is hardware specific!!!** You should always consult the documentation on your particular hardware. Information here is presented for "planning" purposes only - to help you figure out which of the hardware variants will suit the sensors and solenoids present on your engine.

|

||||

This page contains information about how to hook up to rusEFI hardware, in general. It's not intended to be a guide to a specific hardware variant - rather, how to figure out what you're going to need to run the different kinds of hardware you'd find in an engine bay.

|

||||

|

||||

**WARNING: The exact implementation of these pins is hardware specific!!!**

|

||||

You should always consult the documentation on your particular hardware. The information here is presented for "planning" purposes only - to help you figure out which of the hardware variants will suit the sensors and solenoids present on your engine.

|

||||

|

||||

|

||||

## Fuel injectors

|

||||

|

||||

As of May 2020, only saturated (high impedance, >8 ohms) port injectors are supported. All hardware variants are built around the concept of one ECU pin controlling one fuel injector. The use of multiple injectors on one ECU output must be very carefully evaluated to avoid overloading drivers. One injector may also be used for all cylinders("single point"). A pair of injectors can be wired together and fired simultaneously, as in 4 pairs of injectors on a V8. It's possible but not intuitive to configure two banks of multiple cylinders of injectors alternating fire. It is recommended to use one injector per cylinder. As of May 2020, staged injection with multiple injectors per cylinder is possible in hardware but the software is not yet ready.

|

||||

As of May 2020, only saturated (high impedance, >8 ohms) port injectors are supported. All hardware variants are built around the concept of one ECU pin controlling one fuel injector. The use of multiple injectors on one ECU output must be very carefully evaluated to avoid overloading drivers. One injector may also be used for all cylinders ("single point"). A pair of injectors can be wired together and fired simultaneously, as in 4 pairs of injectors on a V8. It's possible but not intuitive to configure two banks of multiple cylinders of injectors alternating fire. It is recommended to use one injector per cylinder. As of May 2020, staged injection with multiple injectors per cylinder is possible in hardware but the software is not yet ready.

|

||||

|

||||

You do **not** need to wire injectors in a particular way. Cylinder #1 (as numbered by the manufacturer) does not need to be wired to injector #1 on the ECU pinout. Likewise, the 3rd (for example) injector in the firing order does **not** need to be wired to INJ#3 on the ECU. Order of firing / phasing can be adjusted in software. Any injector driver output can be used to drive any injector.

|

||||

You do **not** need to wire injectors in a particular way. Cylinder #1 (as numbered by the manufacturer) does not need to be wired to injector #1 on the ECU pinout. Likewise, the 3rd (for example) injector in the firing order does **not** need to be wired to INJ#3 on the ECU. Order of firing / phasing can be adjusted in software. Any injector driver output can be used to drive any injector.

|

||||

|

||||

Bottom line: as long as the hardware variant has at least as many injector outputs as your engine has cylinders, you will be able to run one injector per cylinder.

|

||||

|

||||

|

||||

## Coils

|

||||

|

||||

As of May 2020, most hardware variants support only logic level drive for coils. This means GM LSx, IGN1A, Denso coil stick, etc. (others may too - these are just examples) that have built in ignitors will work. You should consult the documentation for both the coils and rusEFI hardware you are using to determine whether you can directly wire the coils or an external ignitor/something else is required. Note: coil outputs are among the **least** robust (in terms of tolerating shorts, excessive voltages, etc.) on many hardware variants, including Proteus. Double check your wiring!

|

||||

As of May 2020, most hardware variants support only logic level drive for coils. This means GM LSx, IGN1A, Denso coil stick, etc. (others may too - these are just examples) that have built in ignitors will work. You should consult the documentation for both the coils and the rusEFI hardware you are using to determine whether you can directly wire the coils or an external ignitor/something else is required. Note: coil outputs are among the **least** robust (in terms of tolerating shorts, excessive voltages, etc.) on many hardware variants, including Proteus. Double check your wiring!

|

||||

|

||||

Like injectors, all coil outputs are interchangeable. Coil outputs do not need to be used sequentially and order of firing / phasing can be adjusted in software. Waste fire (one coil fires two cylinders) and distributor (one coil mechanically multiplexed among all cylinders) modes are supported in addition to coil-per-cylinder direct fire. Rare "dual distributor" mode is also supported for engines like older BMW V12 and Toyota 1UZ.

|

||||

Like injectors, all coil outputs are interchangeable. Coil outputs do not need to be used sequentially and order of firing / phasing can be adjusted in software. Waste fire (one coil fires two cylinders) and distributor (one coil mechanically multiplexed among all cylinders) modes are supported in addition to coil-per-cylinder direct fire. Rare "dual distributor" mode is also supported for engines like older BMW V12 and Toyota 1UZ.

|

||||

|

||||

Bottom line: as long as the hardware variant has at least as many coil outputs as your engine has cylinders, you will be able to run one coil per cylinder.

|

||||

|

||||

|

||||

## General purpose outputs

|

||||

|

||||

The two main types of output are "low side" and "high side."

|

||||

|

||||

Low side outputs are used to control things in the engine bay that have one terminal permanently connected to battery voltage. The ECU supplies the ground side of the circuit to turn things on.

|

||||

Low side outputs are used to control things in the engine bay that have one terminal permanently connected to battery voltage. The ECU supplies the ground side of the circuit to turn things on.

|

||||

|

||||

High side outputs are used to control things in the engine bay that have one terminal permanently connected to ground. The ECU supplies battery voltage to the circuit to turn things on.

|

||||

High side outputs are used to control things in the engine bay that have one terminal permanently connected to ground. The ECU supplies battery voltage to the circuit to turn things on.

|

||||

|

||||

All general purpose outputs are available for conditional on/off control via basic conditions. (insert more details here)

|

||||

|

||||

All general purpose outputs can be used by the software-PWM system. The software PWM system can provide approximately 1% duty steps at up to 1Khz. (10uS steps, 1ms cycle) Software PWM can operate at different speeds for different outputs - there is a lot of flexibility. (link to more information)

|

||||

All general purpose outputs can be used by the software-PWM system. The software PWM system can provide approximately 1% duty steps at up to 1Khz. (10uS steps, 1ms cycle) Software PWM can operate at different speeds for different outputs - there is a lot of flexibility. (link to more information)

|

||||

|

||||

|

||||

## Specific Outputs

|

||||

|

||||

|

|

@ -36,24 +43,26 @@ All general purpose outputs can be used by the software-PWM system. The softwar

|

|||

|

||||

Logic exists in the firmware to use several types of idle control valves to regulate idle.

|

||||

|

||||

PWM valves (generally 2 wire) accept a variable duty-cycle square wave to control their position. Any general-purpose output hardware that can handle the electrical load can be configured to control a PWM-style idle valve. Dedicated pins do not need to be allocated for these style valves. Honda, Nissan, Mitsubishi, Subaru, Ford valves are commonly this type.

|

||||

PWM valves (generally 2 wire) accept a variable duty-cycle square wave to control their position. Any general-purpose output hardware that can handle the electrical load can be configured to control a PWM-style idle valve. Dedicated pins do not need to be allocated for these style valves. Honda, Nissan, Mitsubishi, Subaru, Ford valves are commonly this type.

|

||||

|

||||

Bipolar stepper motors (generally 4 wire) have two coils that are energized in different patterns in order to move the valve open or closed, one step at a time. Bipolar stepper motors require **two H-Bridges** (Proteus) to control one bipolar stepper idle valve. Alternatively, a dedicated stepper driver IC can be used(Prometheus?) or added via a drop-in adapter board. GM, Toyota commonly use these.

|

||||

Bipolar stepper motors (generally 4 wire) have two coils that are energized in different patterns in order to move the valve open or closed, one step at a time. Bipolar stepper motors require **two H-Bridges** (Proteus) to control one bipolar stepper idle valve. Alternatively, a dedicated stepper driver IC can be used(Prometheus?) or added via a drop-in adapter board. GM, Toyota commonly use these.

|

||||

|

||||

Unipolar stepper valves are not supported by any hardware variants at this time. (May 2020) Chrysler commonly used these.

|

||||

|

||||

Unipolar stepper valves are not supported by any hardware variants at this time. (May 2020) Chrysler commonly used these.

|

||||

|

||||

### Drive by Wire support

|

||||

|

||||

Logic exists in the firmware to control a drive by wire throttle body, including using it to idle. A single H-bridge is required to control a single DBW throttle body. Multiple DBW throttle bodies can be simultaneously controlled as long as sufficient H-bridge drivers exist to control them. A drive by wire pedal (Accelerator Pedal Position / APP) is generally used to provide input from the driver. Want to know more? There is a [HOWTO](HOWTO_electronic_throttle_body) you should read.

|

||||

Logic exists in the firmware to control a drive by wire throttle body, including using it to idle. A single H-bridge is required to control a single DBW throttle body. Multiple DBW throttle bodies can be simultaneously controlled as long as sufficient H-bridge drivers exist to control them. A drive by wire pedal (Accelerator Pedal Position / APP) is generally used to provide input from the driver. Want to know more? here is a [HOWTO](HOWTO_electronic_throttle_body) you should read.

|

||||

|

||||

|

||||

### Main Relay support

|

||||

|

||||

Most hardware variants are set up to provide control over a main relay or auto-shutdown relay. The rusEFI ECU typically has two power feeds. Key-on power is supplied to the ECU in order to power the CPU and logic core of the ECU. High side drivers, H Bridges and other power switches are then powered by a "main relay" that is energized under the control of the ECU. Battery / continuous power is not required for setting retention.

|

||||

Most hardware variants are set up to provide control over a main relay or auto-shutdown relay. The rusEFI ECU typically has two power feeds. Key-on power is supplied to the ECU in order to power the CPU and logic core of the ECU. High side drivers, H Bridges and other power switches are then powered by a "main relay" that is energized under the control of the ECU. Battery / continuous power is not required for setting retention.

|

||||

|

||||

|

||||

## Specific Function Inputs

|

||||

|

||||

Engine position (crank, cam) are specific inputs required. Hall Effect (square wave / magnetic or optical) and Variable Reluctance (VR / inductive) sensors are supported.

|

||||

Engine position (crank, cam) are specific inputs required. Hall Effect (square wave / magnetic or optical) and Variable Reluctance (VR / inductive) sensors are supported.

|

||||

|

||||

Some hardware variants have a provision for knock sensors.

|

||||

|

||||

|

|

@ -65,4 +74,4 @@ Digital inputs need to have a pull resistor in order to ensure they do not pick

|

|||

|

||||

As of May 2020, analog inputs are broken into two basic categories:

|

||||

1. "Thermistor" inputs have an internal pull up to 5V (varies according to hardware: 2.7k on proteus) to make connecting to sensors like coolant temp and air temperature easier. When using a thermistor input, one terminal of the sensor is connected to the ECU and the "other" end of your sensor should be connected to sensor ground. Note: many "single wire" thermistors used for coolant temperature have metal threads which make contact with the cylinder head/block, providing the "other" terminal without a wire.

|

||||

1. "Analog Voltage" inputs have a **weak** pull-down to sensor ground (varies according to hardware: 500k on proteus) and are intended for things like MAP or TPS sensors that drive a voltage. On most hardware implementations(double check your hardware!), these inputs are also protected against excessive voltage. The combination of an internal pull-down resistor and built-in protection means that analog inputs can safely double as "active high" inputs, where battery voltage indicates that a switch is high.

|

||||

2. "Analog Voltage" inputs have a **weak** pull-down to sensor ground (varies according to hardware: 500k on proteus) and are intended for things like MAP or TPS sensors that drive a voltage. On most hardware implementations(double check your hardware!), these inputs are also protected against excessive voltage. The combination of an internal pull-down resistor and built-in protection means that analog inputs can safely double as "active high" inputs, where battery voltage indicates that a switch is high.

|

||||

|

|

@ -7,6 +7,6 @@

|

|||

Gasoline Direct Injection requires a few additional components on top of port injection:

|

||||

1) High voltage injection control - we have rusEfi MC33816 board which has clicked injector on a bench https://www.youtube.com/watch?v=MI0gJ4th9Tg

|

||||

|

||||

1) high pressure fuel pump solenoid control - we have nothing

|

||||

2) High pressure fuel pump solenoid control - we have nothing

|

||||

|

||||

1) target fuel pressure logic - we have nothing

|

||||

3) Target fuel pressure logic - we have nothing

|

||||

|

|

@ -1,15 +1,15 @@

|

|||

# Ignition FAQ

|

||||

|

||||

One of the most common themes with rusEFI is people wanting to know more about igntion and what ignition hardware rusEFI can work with.

|

||||

One of the most common themes with rusEFI is people wanting to know more about ignition and what ignition hardware rusEFI can work with.

|

||||

The topics below are an attempt to cover as many of the common key questions we get asked.

|

||||

|

||||

---

|

||||

|

||||

## Will rusEFI work with my "XYZ" coils?

|

||||

In theory rusEFI will work with any coils from nearly any vehicle produced since the daimler motor carriage of 1901.

|

||||

In reality there are some practicalities to that mean some coils are easier than others.

|

||||

In reality there are some practicalities that make some coils easier than others.

|

||||

|

||||

The rusEFI ignition circuits are designed to work at 5v and are not designed to resist the large currents produced when controlling an ignition coil. "Well that's is no good!" I hear you think, actually it is perfectly fine provided certain conditions are met.

|

||||

The rusEFI ignition circuits are designed to work at 5v and are not designed to resist the large currents produced when controlling an ignition coil. "Well that's is no good!" I hear you think - actually, it is perfectly fine provided certain conditions are met.

|

||||

|

||||

The outputs of the rusEFI hardware are able to operate an ignition coil driver (IGBT) but not the coil directly.

|

||||

This means that more modern "smart" coils that have an IGBT built into the coil can be driven directly.

|

||||

|

|

@ -23,27 +23,29 @@ Quite simply for the same reasons modern ECUs do not have them either.

|

|||

1. It reduces the number of parts needed for the ECU and thus the cost

|

||||

2. It means the IGBT component is replaceable as they do sometimes fail

|

||||

3. It moves the electrically noisy high current/voltage components away from the sensitive MCU

|

||||

4. The shorter the physical length of these (actually quite sensitive) high current/voltage circuits the better, it reduces the total EMF signature of the vehicle, it reduces the weight of the vehicle as the wires can be smaller and most importantly it reduces the losses and means there is more energy available for the spark.

|

||||

4. The shorter the physical length of these (actually quite sensitive) high current/voltage circuits the better; it reduces the total EMF signature of the vehicle, it reduces the weight of the vehicle as the wires can be smaller and most importantly it reduces the losses and means there is more energy available for the spark.

|

||||

|

||||

Most more modern ignition coils are smart for these exact reasons and in order to work with these nice modern, high power low weight COP coils we have a 5v output.

|

||||

|

||||

---

|

||||

|

||||

## OK you made your point but what coils do I need?

|

||||

## You made your point but what coils do I need?

|

||||

|

||||

That all depends if you want to buy new coils or already have some. In general we would advise to buy "smart coils" but we are also big fans of working with what you have or raiding the junk yard (read this as we are tight).

|

||||

We have attempted to compile a list of coils [here.](Vault_Of_Ignition_Parts)

|

||||

|

||||

---

|

||||

|

||||

## Thanks but that really did not help, please tell me exactly what to do?

|

||||

|

||||

OK, ok, this question needs tackling in several parts, please pick the option you need below:

|

||||

Ok, this question needs tackling in several parts, please pick the option you need below:

|

||||

|

||||

<details><summary><u>I want to buy new coils</u></summary>

|

||||

|

||||

If you are looking to buy new coils then we would recommend taking a look at the list of Ignition coils that have been tried with rusEFI.

|

||||

[List of ignition coils](Vault_Of_Ignition_Parts)

|

||||

In general though we recommend trying to get a tried and tested solution and getting coils that are easily available in your local area.

|

||||

There are lots of tried and tested options that can be found by [**searching the forum.**](https://rusefi.com/forum/search.php)

|

||||

|

||||

</details>

|

||||

|

||||

|

|

@ -54,17 +56,18 @@ In general though we recommend trying to get a tried and tested solution and get

|

|||

|

||||

Great, then you can wire them directly to the ECU.

|

||||

However please take care to check that tht coils you have really do incorporate the ignition driver into the coil.

|

||||

Having 3 or 4 connectors pins is not a guarantee that a coils is a "smart" coil.

|

||||

Having 3 or 4 connectors pins is not a guarantee that a coils is a "smart" coil.

|

||||

There is some information on known smart coils and how to work out if you have a smart coil that can be found by [**searching the forum.**](https://rusefi.com/forum/search.php)

|

||||

|

||||

</details>

|

||||

|

||||

<details><summary><u>My coils are older dumb coils</u></summary>

|

||||

|

||||

Great, same as the smart coils please double check your coils are actually simple coils without built in ignition modules.

|

||||

Great - same as the smart coils, please double check your coils are actually simple coils without built in ignition modules.

|

||||

You will need to source an external ignition module to go between the ECU and the coils.

|

||||

These are generally quite cheap and can be found on some cars in the junk yard. We also made our own simple module [here](fix link)

|

||||

|

||||

There are some tested Ignition modules on the Ignition components list.

|

||||

There are some tested Ignition modules on the Ignition components list and some can be found by [**searching the forum.**](https://rusefi.com/forum/search.php)

|

||||

[List of ignition components](Vault_Of_Ignition_Parts)

|

||||

|

||||

</details>

|

||||

|

|

@ -76,7 +79,8 @@ There are some tested Ignition modules on the Ignition components list.

|

|||

## I need an ignition module, what now?

|

||||

|

||||

Most older coils will need this and some cars have them as standard.

|

||||

These are not to be confused with the EDIS module that some ECUs require that is a more complex unit that does some of the functions for those simpler ECUs.

|

||||

These are not to be confused with the EDIS module that some ECUs require that is a more complex unit that does some of the functions for those simpler ECUs.

|

||||

Lots of users have already had to tackle this issue so there is a host of options that can be found by [**searching the forum.**](https://rusefi.com/forum/search.php)

|

||||

|

||||

There are several available modules some are listed on the Ignition components list.

|

||||

[List of ignition components](Vault_Of_Ignition_Parts)

|

||||

|

|

@ -86,4 +90,15 @@ There are several available modules some are listed on the Ignition components l

|

|||

## What about adding IGBTs on the board to drive coils directly?

|

||||

|

||||

Actually we already have this in the form of the Prometheus and Hellen boards.

|

||||

These boards are intended as all in one solutions.

|

||||

These boards are intended as all in one solutions.

|

||||

|

||||

---

|

||||

|

||||

## I have a coil with 3/4/5 pins, does this mean it is a smart coil?

|

||||

|

||||

Absolutely not.

|

||||

Some Bosch dumb coils have 3 pins, one is used for ignition misfire monitoring.

|

||||

Wasted spark coils can share one common pin and then have a single pin for each coil pair. Resulting in a dumb coil with 3-5 pins.

|

||||

Some wasted spark coils have 2 pins for each coil pair inside the pack.

|

||||

|

||||

This means it is vitally necessary to check the requirements of your actual coils by reviewing the wiring diagrams or [**searching the forum.**](https://rusefi.com/forum/search.php)

|

||||

|

|

@ -0,0 +1 @@

|

|||

Please see here: https://rusefi.com/wiki/index.php?title=Manual:First_engine_start

|

||||

|

|

@ -1 +0,0 @@

|

|||

https://rusefi.com/wiki/index.php?title=Manual:First_engine_start

|

||||

|

|

@ -1,17 +1,17 @@

|

|||

# Acceleration_Compensation

|

||||

|

||||

Acceleration Compensation is required in an EFI system to modify the fuel injection to compensate for the deviation in AFR caused by the change of conditions in the inlet manifold.

|

||||

When an engine changes load the depression in the inlet manifold changes, during an increase of load the depression increases and this causes fuel to drop out of suspension and collect on the walls of the intake manifold.

|

||||

Because of this fuel drop out, instead of being drawn into the cylinders the fuel momentarily remains on the walls of the inlet manifold. The result of this is the lean AFR spike you can often see on poorly tuned vehicles when giving a sudden increase of throttle.

|

||||

Acceleration Compensation is required in an EFI system to modify the fuel injection to compensate for the deviation in AFR caused by the change of conditions in the inlet manifold.

|

||||

|

||||

When an engine changes load the depression in the inlet manifold changes; during an increase of load the depression increases and this causes fuel to drop out of suspension and collect on the walls of the intake manifold. Because of this fuel drop out, instead of being drawn into the cylinders, the fuel momentarily remains on the walls of the inlet manifold. The result of this is the lean AFR spike you can often see on poorly tuned vehicles when giving a sudden increase of throttle.

|

||||

|

||||

rusEFI has implemented several strategies that attempt to compensate for this physical phenomenon. These are detailed in their own specific pages but a brief overview is shown below.

|

||||

rusEFI has implemented several strategies that attempt to compensate for this physical phenomenon. These are detailed in their own specific pages, but a brief overview is shown below.

|

||||

|

||||

It is important to note that the Acceleration compensation is not intended to increase the amount of fuel in order to increase power during acceleration, that is the purpose of the AFR table or VE table, this compensation is purely intended to correct for the fuel dropping out of suspension.

|

||||

N.B. This is also why I refer to it as "Acceleration Compensation" rather than "Acceleration Enrichment", the second term implies the wrong purpose.

|

||||

It is important to note that the Acceleration Compensation is not intended to increase the amount of fuel in order to increase power during acceleration - that is the purpose of the AFR table or VE table, whereas this compensation is purely intended to correct for the fuel dropping out of suspension.

|

||||

N.B. This is also why I refer to it as "Acceleration Compensation" rather than "Acceleration Enrichment", as the second term implies the wrong purpose.

|

||||

|

||||

# TPS based

|

||||

|

||||

This is the most simple of the methods, it uses the change in TPS position over time to decide on an additional quantity of fuel to inject.

|

||||

The simplest method, this uses the change in TPS position over time to decide on an additional quantity of fuel to inject.

|

||||

It is most similar to a carburetors accelerator pump in operation.

|

||||

|

||||

# Wall Wetting

|

||||

|

|

|

|||

|

|

@ -2,23 +2,23 @@

|

|||

|

||||

AlphaN is a method of fueling that uses the angle of the TPS (Alpha) and the RPM of the engine (N) to determine how much fuel should be injected.

|

||||

|

||||

It is a very simply method that simply uses the Alpha as the Y axis and N as the X axis of the fuel table.

|

||||

It is a very simple method that simply uses the Alpha as the Y axis and N as the X axis of the fuel table.

|

||||

|

||||

This method is most commonly used on pure race cars that are willing to sacrifice an amount of drivability for simplicity or on installations where there is a great difficulty reading for a MAP or MAF sensor.

|

||||

This method is most commonly used on pure race cars that are willing to sacrifice an amount of drivability for simplicity, or on installations where there is a great difficulty reading for a MAP or MAF sensor.

|

||||

An example of this would be ITBs.

|

||||

|

||||

It is not suggested that this method is used with rusEFI as we have implemented very good windowing and smoothing of MAP sensor signals and this allows for the speed density method to be used reliably on systems where it would not traditionally function well.

|

||||

It is not suggested that this method is used with rusEFI as we have implemented very good windowing and smoothing of MAP sensor signals, which allows for the speed density method to be used reliably on systems where it would not traditionally function well.

|

||||

However we are aware that there are many users that would still prefer to use this method so it has been provided.

|

||||

|

||||

# The detail

|

||||

|

||||

fuel_squirt_duration = injector_lag_curve_lookup(V_BATT) + warm_up_curve_lookup(COOLANT_TEMPERATURE) * intake_air_correction_curve_lookup(INTAKE_AIR_TEMP) * fuel_table_lookup(RPM, TPS)

|

||||

|

||||

where TPS is the reading at the start of engine cycle

|

||||

Where TPS is the reading at the start of engine cycle

|

||||

|

||||

# How to tune

|

||||

|

||||

The AlphaN system in rusEFI can be tuned in the same way as all other stand alone ECUs, it is simply a case of inputting the required fuel values in the main fuel table.

|

||||

The AlphaN system in rusEFI can be tuned in the same way as all other standalone ECUs, it is simply a case of inputting the required fuel values in the main fuel table.

|

||||

|

||||

It is planned that a future update will modify this table to be a VE table in a similar way to several other aftermarket systems. This will be done for simplicity of use.

|

||||

|

||||

|

|

|

|||

|

|

@ -8,7 +8,7 @@ Airfuel.jpg

|

|||

|

||||

Original graphic found here [1]

|

||||

|

||||

Most people who are installing tune-able ECU's like rusEFI are looking for more power at the track. However your fuel weight advantage is also commonly important. So it is common that an engine will be tuned for peak power when over a certain load, and peak economy when at a cruise load. OEM's are often concerned with minimal environmental impact, so they may tune to a different AFR. Once you have decided on what your AFR strategy is going to be, you'll have to tune rusEFI to deliver that strategy. As well you will probably use an wide band oxygen sensor to measure your AFR and ensure that your are meeting your desired AFT plan.

|

||||

Most people who are installing tune-able ECU's like rusEFI are looking for more power at the track. However your fuel weight advantage is also commonly important. So it is common that an engine will be tuned for peak power when over a certain load, and peak economy when at a cruise load. OEM's are often concerned with minimal environmental impact, so they may tune to a different AFR. Once you have decided on what your AFR strategy is going to be, you'll have to tune rusEFI to deliver that strategy. As well you will probably use a wide band oxygen sensor to measure your AFR and ensure that you are meeting your desired AFR target.

|

||||

|

||||

# Supported fuel control algorithms

|

||||

rusEFI supports mono, individual/sequential and batched fuel injection using one of the following fuel control algorithms:

|

||||

|

|

|

|||

|

|

@ -1,16 +1,16 @@

|

|||

# RusEFI (RE) PCB Configurations

|

||||

When ordering rusEFI the ECU boards may be bought in several different stages of assembly completeness. These stages may range from the bare board with no components attached all the way to fully assembled PCBs already in enclosures. What should be ordered by the end user is up to them, their solering skills and capabilities, and how much they value their time.

|

||||

When ordering rusEFI the ECU boards may be bought in several different stages of assembly completeness. These stages may range from the bare board with no components attached all the way to fully assembled PCBs already in enclosures. What should be ordered by the end user is up to them, their soldering skills and capabilities, and how much they value their time.

|

||||

|

||||

1. **Bare PCB**: No components soldered. For the end user, soldering would be required for **ALL** components.

|

||||

|

||||

|

||||

2. **Partially Populated Board**: More than a half of components soldered to it. This board would require the end user to do some SMT and/or through-hole soldering to get a functional board.

|

||||

|

||||

|

||||

|

||||

1. **Fully Populated Board**: No soldering is required by the end user to have a fully functional board but case is not included.

|

||||

3. **Fully Populated Board**: No soldering is required by the end user to have a fully functional board but a case is not included.

|

||||

|

||||

|

||||

1. **Fully Assembled**: All SMT and through hole devices are populated and the board is in a case. The end user does not need to open the case or ever look at the PCB. As far as the end user is concerned the product just needs to be wired in.

|

||||

4. **Fully Assembled**: All SMT and through hole devices are populated and the board is in a case. The end user does not need to open the case or ever look at the PCB. As far as the end user is concerned the product just needs to be wired in.

|

||||

|

||||

|

||||

|

||||

|

|

|

|||

|

|

@ -1,14 +1,14 @@

|

|||

See Hardware/Deucalion/Deucalion_0_1_uart.jpg

|

||||

|

||||

|

||||

|

||||

From right to left:

|

||||

|

||||

Black GND

|

||||

Yellow above GND: +5v supply

|

||||

Blue next to yellow: TXD

|

||||

Green next to blue: RXD

|

||||

* Black GND

|

||||

* Yellow above GND: +5v supply

|

||||

* Blue next to yellow: TXD

|

||||

* Green next to blue: RXD

|

||||

|

||||

Above mentioned four wires is all you need to update firmware in Kinetis and connect to Deucalion via UART.

|

||||

The above mentioned four wires are all you need to update the firmware in Kinetis and connect to Deucalion via UART.

|

||||

|

||||

Another green is another RXD for second UART, another blue is another TXD.

|

||||

|

||||

|

|

|

|||

|

|

@ -1,3 +1,11 @@

|

|||

### Initial kit state:

|

||||

|

||||

All kit PCBs come pre-programmed and verified. No firmware upload required right after soldering. Actually your microRusEFI would

|

||||

communicate via USB if you solder just USB connector or feed USB via 48 pin connector.

|

||||

|

||||

https://www.youtube.com/watch?v=3vWbIECoLg8

|

||||

|

||||

|

||||

## HOWTO microRusEfi Kit

|

||||

|

||||

|

||||

|

|

|

|||

Binary file not shown.

6

Home.md

6

Home.md

|

|

@ -9,9 +9,9 @@ You have found the rusEFI wiki main page. Here you will find information related

|

|||

**This project is NOT for emissions controlled or safety critical applications. This project is for race cars, snow blowers, fixed engine applications, and science experiments.**

|

||||

|

||||

|

||||

In order to use rusEFI you would need to acquire or fabricate one of the [supported boards](Hardware). You can also design you custom board if desired.

|

||||

In order to use rusEFI you will need to acquire or fabricate one of the [supported boards](Hardware). You can also design your own custom board if so desired.

|

||||

|

||||

You can use rusEFI PC simulator to try rusEfi. PC simulator Windows binaries are included into [rusEFI Bundle](Download), Unix version of PC simulator could be compiled from [source code](https://github.com/rusefi/rusefi/tree/master/simulator).

|

||||

You can use rusEFI PC simulator to try rusEFI. PC simulator Windows binaries are included into [rusEFI Bundle](Download), and the Unix version of PC simulator could be compiled from [source code](https://github.com/rusefi/rusefi/tree/master/simulator).

|

||||

|

||||

## Features

|

||||

|

||||

|

|

@ -23,7 +23,7 @@ You can use rusEFI PC simulator to try rusEfi. PC simulator Windows binaries are

|

|||

|

||||

4. And many more! See [rusEFI-project](rusEFI-project) for more details.

|

||||

|

||||

**As of April 2020 rusEFI has not yet had following features:**

|

||||

**As of April 2020 rusEFI has not yet had the following features:**

|

||||

1. rusEFI has not yet been used to manage a diesel engine.

|

||||

|

||||

2. rusEFI has not yet been used to manage a direct injection gasoline engine.

|

||||

|

|

|

|||

|

|

@ -6,7 +6,9 @@ See also [Miata](Miata)

|

|||

|

||||

microRusEFI should be set for Hall

|

||||

|

||||

[Schematics](https://github.com/rusefi/rusefi_documentation/raw/master/Hardware/pnp_microRusEfi_48na/microrusefi48adapter.pdf)

|

||||

[Schematics 0.2](https://github.com/rusefi/rusefi_documentation/raw/master/Hardware/pnp_microRusEfi_48na/microrusefi48adapter_0.2.pdf)

|

||||

|

||||

[Schematics 0.1](https://github.com/rusefi/rusefi_documentation/raw/master/Hardware/pnp_microRusEfi_48na/microrusefi48adapter_0.1.pdf)

|

||||

|

||||

|

||||

https://rusefi.com/wiki/index.php?title=Vehicle:Mazda_Miata_1990

|

||||

|

|

@ -18,6 +20,8 @@ https://rusefi.com/wiki/index.php?title=Vehicle:Mazda_Miata_1994

|

|||

https://rusefi.com/wiki/index.php?title=Vehicle:Mazda_Miata_1995

|

||||

|

||||

|

||||

[InteractiveBOM](https://rusefi.com/docs/ibom/hw48na_V0.1.html)

|

||||

[InteractiveBOM 0.2](https://rusefi.com/docs/ibom/hw48na_V0.2.html)

|

||||

|

||||

[InteractiveBOM 0.1](https://rusefi.com/docs/ibom/hw48na_V0.1.html)

|

||||

|

||||

https://www.youtube.com/watch?v=vleG0Jp5isY

|

||||

|

|

@ -17,7 +17,7 @@

|

|||

|

||||

<details><summary><u>Coils and ignition modules</u></summary>

|

||||

|

||||

* List of tested coils - Coming Soon

|

||||

* List of tested Ignition modules and IGBTs - Coming Soon

|

||||

* [List of tested coils](Vaut_Of_Ignition_Parts)

|

||||

* [List of tested Ignition modules and IGBTs](Vaut_Of_Ignition_Parts)

|

||||

|

||||

</details>

|

||||

|

|

@ -0,0 +1,18 @@

|

|||

# The Vault Of Ignition Parts

|

||||

|

||||

### This page is intended as a container for all trialed ignition components that are external to the ECU.

|

||||

|

||||

---

|

||||

|

||||

## Ignition coils

|

||||

### Smart coils

|

||||

* LSx ignition coils - Considered the cheap goto for US users. Can be purchased cheaply from junkyards and Ebay.

|

||||

|

||||

### Dumb coils

|

||||

* BMW M50 coils - Tested and working with VW ignition module

|

||||

|

||||

---

|

||||

|

||||

## Ignition Modules

|

||||

* VW 1.8t 4 cylinder module - PN 4D0905351

|

||||

Tested and working with BMW Coils, uses a pair of ampseal plugs (easily available on ebay). Wiring layout available on the forum.

|

||||

|

|

@ -3,6 +3,7 @@

|

|||

|

||||

# Getting Started

|

||||

|

||||

- [How to search the Wiki](HOWTO-Search-on-rusEFI-wiki)

|

||||

- [Quick Start](HOWTO_quick_start)

|

||||

- [How to ask questions](HOWTO_ask_questions)

|

||||

- [Support](Support)

|

||||

|

|

|

|||

|

|

@ -0,0 +1,7 @@

|

|||

* 61.35-8 382 455 "Anti Theft Control Module"

|

||||

* 34.52-1 164 245 "Acceleration Turn Speed Sensor" 34521164245

|

||||

* 61.35-8 378 631 "General Body Control"

|

||||

* 1 095 326 Acceleration Sensor Module: interesting, is this analog output or CAN?!

|

||||

* 0130002830 little cooling blower: only three wires? Is this engine control unit cooling system?!

|

||||

|

||||

|

||||

|

|

@ -1,5 +1,5 @@

|

|||

|

||||

[Frankenso](https://rusefi.com/wiki/index.php?title=Manual:Hardware_Frankenso_board) board was designed to be used on Mazda Miata NA6 as a plug-and-play solution

|

||||

The [Frankenso](https://rusefi.com/wiki/index.php?title=Manual:Hardware_Frankenso_board) board was designed to be used on Mazda Miata NA6 as a plug-and-play solution.

|

||||

|

||||

## Stage 0

|

||||

|

||||

|

|

@ -21,7 +21,7 @@ On NA6 Spark #1 and Spark #3 would audibly click if you use bench Spark Test but

|

|||

Because of wasted spark wiring Spark #2 and Spark #4 are not expected to click.

|

||||

|

||||

On NA6 Injector #1 and Injector #2 would audibly click if you use bench Injector Test button.

|

||||

Because of batch injection wirint Injectors #3 and #4 are not expected to click.

|

||||

Because of batch injection wiring Injectors #3 and #4 are not expected to click.

|

||||

|

||||

All you need is a relatively quiet surroundings and you would hear both spark and injectors. Injectors

|

||||

are louder, spark is less loud but also totally audible. Both Test buttons are expected to

|

||||

|

|

@ -29,11 +29,11 @@ produce three clicks a second after you press the button in the software.

|

|||

|

||||

#### Wideband O2 sensor wire WBO

|

||||

|

||||

You would really need a wideband sensor. Here is middle plug pinout to wire external wideband controller - +12v would feed external controller and analog output signal would provide rusEfi ECU with air/fuel ratio information.

|

||||

You would really need a wideband sensor. Here is the middle plug pinout to wire an external wideband controller - +12v would feed external controller and analog output signal would provide rusEfi ECU with air/fuel ratio information.

|

||||

|

||||

|

||||

|

||||

A small flat screw driver and small pliers would allow you to move side latches and open the cap.

|

||||

A small flat screw driver and small pliers allow you to move side latches and open the cap.

|

||||

Insert supplied extra pin wire (pin on this picture) and close the latches. Done!

|

||||

|

||||

|

||||

|

|

|

|||

|

|

@ -1,31 +1,19 @@

|

|||

Legacy HW wiki https://rusefi.com/wiki/index.php?title=Manual:Hardware_Frankenso_board

|

||||

Legacy HW wiki here: https://rusefi.com/wiki/index.php?title=Manual:Hardware_Frankenso_board

|

||||

|

||||

|

||||

Q: Why three USB connectors?

|

||||

**Q:** Why three USB connectors?

|

||||

|

||||

A: https://rusefi.com/forum/viewtopic.php?f=4&t=1418

|

||||

**A:** https://rusefi.com/forum/viewtopic.php?f=4&t=1418

|

||||

|

||||

|

||||

|

||||

|

||||

|

||||

|

||||

|

||||

|

||||

|

||||

|

||||

|

||||

|

||||

|

||||

|

||||

Pinouts

|

||||

**Pinouts**

|

||||

|

||||

https://rusefi.com/wiki/index.php?title=Vehicle:Mazda_Miata_2003

|

||||

|

||||

https://rusefi.com/wiki/index.php?title=Vehicle:Mazda_Miata_2003_alt

|

||||

|

||||

|

||||

red 2003 VVT test mule Miata NB2 #27

|

||||

**red 2003 VVT test mule Miata NB2 #27**

|

||||

|

||||

https://rusefi.com/forum/viewtopic.php?f=3&t=1095

|

||||

|

||||

|

|

|

|||

|

|

@ -9,31 +9,31 @@ Throttle body 17452071

|

|||

|

||||

ECU#1

|

||||

|

||||

|

||||

ECU#2

|

||||

|

||||

|

||||

ECU#3

|

||||

|

||||

|

||||

ECU#4

|

||||

|

||||

|

||||

ECU#5

|

||||

|

||||

|

||||

Charging

|

||||

|

||||

Charging

|

||||

|

||||

|

||||

Shift Interlock

|

||||

|

||||

|

||||

|

||||

Starter

|

||||

|

||||

|

||||

|

||||

Washer

|

||||

|

||||

|

||||

|

||||

|

||||

|

||||

Vin Registry http://www.e38registry.org/e38-production-numbers/

|

||||

|

|

|

|||

|

|

@ -1,7 +0,0 @@

|

|||

61.35-8 382 455 "Anti Theft Control Module"

|

||||

34.52-1 164 245 "Acceleration Turn Speed Sensor" 34521164245

|

||||

61.35-8 378 631 "General Body Control"

|

||||

1 095 326 Acceleration Sensor Module: interesting, is this analog output or CAN?!

|

||||

0130002830 little cooling blower: only three wires? Is this engine control unit cooling system?!

|

||||

|

||||

|

||||

Loading…

Reference in New Issue