automated md lint fixes

This commit is contained in:

parent

b7a57b8d05

commit

948fad34c0

|

|

@ -13,8 +13,6 @@

|

|||

|

||||

|

||||

|

||||

|

||||

# Starting with Theft

|

||||

|

||||

|

||||

|

||||

|

|

|

|||

|

|

@ -5,4 +5,3 @@ M104 wasted spark

|

|||

|

||||

|

||||

|

||||

|

||||

|

|

|

|||

38

1999-e320.md

38

1999-e320.md

|

|

@ -1,48 +1,40 @@

|

|||

|

||||

|

||||

[Mercedes-Benz M112 Engine - Wikipedia]](https://en.wikipedia.org/wiki/Mercedes-Benz_M112_engine)

|

||||

[Mercedes-Benz M112 Engine - Wikipedia]](<https://en.wikipedia.org/wiki/Mercedes-Benz_M112_engine>)

|

||||

|

||||

# 99 E320

|

||||

|

||||

| Connector/ Pin Number | OEM Color | Name / Function |

|

||||

| Connector/ Pin Number | OEM Color | Name / Function |

|

||||

| --------------------- |------- |---------------- |

|

||||

| A3 | BRN | KL31(GND) Ground Ignition earth |

|

||||

| A7 | BRN | Ground |

|

||||

| A8 | BRN | Ground |

|

||||

|

||||

|

||||

| Connector/ Pin Number | OEM Color | Name / Function |

|

||||

| Connector/ Pin Number | OEM Color | Name / Function |

|

||||

| --------------------- |------- |---------------- |

|

||||

| B1 | | |

|

||||

| B2 | | |

|

||||

|

||||

| Connector/ Pin Number | OEM Color | Name / Function |

|

||||

| Connector/ Pin Number | OEM Color | Name / Function |

|

||||

| --------------------- |------- |---------------- |

|

||||

| C8 | | |

|

||||

| C8 | | |

|

||||

|

||||

| Connector/ Pin Number | OEM Color | Name / Function |

|

||||

| Connector/ Pin Number | OEM Color | Name / Function |

|

||||

| --------------------- |------- |---------------- |

|

||||

| D8 | | |

|

||||

| D8 | | |

|

||||

|

||||

|

||||

| Connector/ Pin Number | OEM Color | Name / Function |

|

||||

| Connector/ Pin Number | OEM Color | Name / Function |

|

||||

| --------------------- |------- |---------------- |

|

||||

| E1 | GRY\RED | INJECTOR NUMBER 2 |

|

||||

| E2 | GRY\YEL | INJECTOR NUMBER 5 |

|

||||

| E13 | GRY\GRN | INJECTOR NUMBER 3 |

|

||||

| E1 | GRY\RED | INJECTOR NUMBER 2 |

|

||||

| E2 | GRY\YEL | INJECTOR NUMBER 5 |

|

||||

| E13 | GRY\GRN | INJECTOR NUMBER 3 |

|

||||

| E14 | GRY\VLO | INJECTOR NUMBER 6 |

|

||||

| E25 | GRY\BLK | INJECTOR NUMBER 1 |

|

||||

| E26 | GRY\BLU | INJECTOR NUMBER 4 |

|

||||

| E25 | GRY\BLK | INJECTOR NUMBER 1 |

|

||||

| E26 | GRY\BLU | INJECTOR NUMBER 4 |

|

||||

|

||||

|

||||

|

||||

|

||||

|

||||

|

||||

|

||||

| Connector/ Pin Number | OEM Color | Name / Function |

|

||||

| Connector/ Pin Number | OEM Color | Name / Function |

|

||||

| --------------------- |------- |---------------- |

|

||||

| F4 | VLO | COIL5.1 |

|

||||

| F5 | VLO\WHT | COIL5.3 |

|

||||

|

|

@ -57,12 +49,6 @@

|

|||

| F20 | BLK\WHT | COIL1.3 |

|

||||

| F21 | BLK | COIL1.1 |

|

||||

|

||||

|

||||

|

||||

|

||||

|

||||

|

||||

|

||||

|

||||

|

||||

|

||||

|

|

|

|||

|

|

@ -1,6 +1,6 @@

|

|||

|

||||

|

||||

[Mercedes-Benz M113 Engine - Wikipedia]](https://en.wikipedia.org/wiki/Mercedes-Benz_M113_engine)

|

||||

[Mercedes-Benz M113 Engine - Wikipedia]](<https://en.wikipedia.org/wiki/Mercedes-Benz_M113_engine>)

|

||||

|

||||

# 99 E430

|

||||

|

||||

|

|

|

|||

23

2000-s430.md

23

2000-s430.md

|

|

@ -1,21 +1,19 @@

|

|||

|

||||

|

||||

[Mercedes-Benz M113 Engine - Wikipedia]](https://en.wikipedia.org/wiki/Mercedes-Benz_M113_engine)

|

||||

[Mercedes-Benz M113 Engine - Wikipedia]](<https://en.wikipedia.org/wiki/Mercedes-Benz_M113_engine>)

|

||||

|

||||

# 2000 S430

|

||||

|

||||

|

||||

| Connector/ Pin Number | OEM Color | Name / Function |

|

||||

| Connector/ Pin Number | OEM Color | Name / Function |

|

||||

| --------------------- |------- |---------------- |

|

||||

| E1 | GRY/VIO | INJECTOR NUMBER 6 |

|

||||

| E2 | GRY/GRN | INJECTOR NUMBER 3 |

|

||||

| E3 | GRY/PNK | INJECTOR NUMBER 7 |

|

||||

| E4 | | INJECTOR NUMBER 8 |

|

||||

| E13 | | INJECTOR NUMBER 4 |

|

||||

| E14 | | INJECTOR NUMBER 2 |

|

||||

| E25 | | INJECTOR NUMBER 1 |

|

||||

| E25 | | INJECTOR NUMBER 5 |

|

||||

|

||||

| E1 | GRY/VIO | INJECTOR NUMBER 6 |

|

||||

| E2 | GRY/GRN | INJECTOR NUMBER 3 |

|

||||

| E3 | GRY/PNK | INJECTOR NUMBER 7 |

|

||||

| E4 | | INJECTOR NUMBER 8 |

|

||||

| E13 | | INJECTOR NUMBER 4 |

|

||||

| E14 | | INJECTOR NUMBER 2 |

|

||||

| E25 | | INJECTOR NUMBER 1 |

|

||||

| E25 | | INJECTOR NUMBER 5 |

|

||||

|

||||

|

||||

|

||||

|

|

@ -23,7 +21,6 @@

|

|||

|

||||

|

||||

|

||||

|

||||

# 2000 S500

|

||||

|

||||

|

||||

|

|

|

|||

|

|

@ -2,4 +2,4 @@

|

|||

|

||||

|

||||

|

||||

|

||||

|

||||

|

|

|

|||

|

|

@ -33,9 +33,6 @@

|

|||

| 118 | ? | H-bridge | ETB |

|

||||

| 121 | ? | 12v | +12v from main relay |

|

||||

|

||||

|

||||

|

||||

|

||||

|

||||

|

||||

|

||||

|

|

|

|||

|

|

@ -1,5 +1,4 @@

|

|||

|

||||

|

||||

[page-1](OEM-Docs/VAG/2004-cayenne-3.2-1.pdf)

|

||||

|

||||

[page-2](OEM-Docs/VAG/2004-cayenne-3.2-2.pdf)

|

||||

|

|

@ -7,4 +6,3 @@

|

|||

[page-3](OEM-Docs/VAG/2004-cayenne-3.2-3.pdf)

|

||||

|

||||

[page-4](OEM-Docs/VAG/2004-cayenne-3.2-4.pdf)

|

||||

|

||||

|

|

|

|||

14

3000gt.md

14

3000gt.md

|

|

@ -2,7 +2,6 @@

|

|||

|

||||

[Pinout Spreadsheet](https://docs.google.com/spreadsheets/d/1ZlcC5cdCwjYoV-z49MNaa9zpLiu_ZYBIx5H-j0F6QpI)

|

||||

|

||||

|

||||

# 1994

|

||||

|

||||

DOHC Non-turbo California: 1994 to 1997

|

||||

|

|

@ -12,38 +11,47 @@ DOHC Non-turbo Federal: 1996 to 1997

|

|||

DOHC Turbo: 1994 to 1997

|

||||

|

||||

### 94-1

|

||||

|

||||

|

||||

|

||||

### 94-2

|

||||

|

||||

|

||||

|

||||

### 94-3

|

||||

|

||||

|

||||

|

||||

### 94-4

|

||||

|

||||

|

||||

|

||||

### 94-5

|

||||

|

||||

|

||||

|

||||

### 94-6

|

||||

|

||||

|

||||

|

||||

|

||||

# 1996-1997

|

||||

|

||||

### 96-1

|

||||

|

||||

|

||||

|

||||

### 96-2

|

||||

|

||||

|

||||

|

||||

### 96-3

|

||||

|

||||

|

||||

|

||||

### 96-4

|

||||

|

||||

|

||||

|

||||

### 96-5

|

||||

|

||||

|

||||

|

||||

|

|

|

|||

3

ASIC.md

3

ASIC.md

|

|

@ -1,7 +1,6 @@

|

|||

|

||||

Overview of state of integration between rusEFI and all kinds of ASICs.

|

||||

|

||||

|

||||

# Low side+

|

||||

|

||||

### Mostly implemented

|

||||

|

|

@ -40,5 +39,3 @@ Overview of state of integration between rusEFI and all kinds of ASICs.

|

|||

| MAX31855 | EGT | Not used by anyone |

|

||||

| [MC33972](https://www.nxp.com/docs/en/data-sheet/MC33972.pdf) | Multiple switch detection interface | EG33 board |

|

||||

| | | | | |

|

||||

|

||||

|

||||

|

|

|

|||

|

|

@ -2,27 +2,27 @@

|

|||

|

||||

See also [Fuel Overview](Fuel-Overview)

|

||||

|

||||

Acceleration Compensation is required in an EFI system to modify the fuel injection to compensate for the deviation in AFR caused by the change of conditions in the inlet manifold.

|

||||

|

||||

When an engine changes load the depression in the inlet manifold changes; during an increase of load the depression increases and this causes fuel to drop out of suspension and collect on the walls of the intake manifold. Because of this fuel drop out, instead of being drawn into the cylinders, the fuel momentarily remains on the walls of the inlet manifold. The result of this is the lean AFR spike you can often see on poorly tuned vehicles when giving a sudden increase of throttle.

|

||||

Acceleration Compensation is required in an EFI system to modify the fuel injection to compensate for the deviation in AFR caused by the change of conditions in the inlet manifold.

|

||||

|

||||

When an engine changes load the depression in the inlet manifold changes; during an increase of load the depression increases and this causes fuel to drop out of suspension and collect on the walls of the intake manifold. Because of this fuel drop out, instead of being drawn into the cylinders, the fuel momentarily remains on the walls of the inlet manifold. The result of this is the lean AFR spike you can often see on poorly tuned vehicles when giving a sudden increase of throttle.

|

||||

|

||||

rusEFI has implemented several strategies that attempt to compensate for this physical phenomenon. These are detailed in their own specific pages, but a brief overview is shown below.

|

||||

|

||||

It is important to note that the Acceleration Compensation is not intended to increase the amount of fuel in order to increase power during acceleration - that is the purpose of the AFR table or VE table, whereas this compensation is purely intended to correct for the fuel dropping out of suspension.

|

||||

N.B. This is also why I refer to it as "Acceleration Compensation" rather than "Acceleration Enrichment", as the second term implies the wrong purpose.

|

||||

N.B. This is also why I refer to it as "Acceleration Compensation" rather than "Acceleration Enrichment", as the second term implies the wrong purpose.

|

||||

|

||||

# TPS based

|

||||

# TPS based

|

||||

|

||||

The simplest method, this uses the change in TPS position over time to decide on an additional quantity of fuel to inject.

|

||||

It is most similar to a carburetors accelerator pump in operation.

|

||||

It is most similar to a carburetors accelerator pump in operation.

|

||||

|

||||

# Wall Wetting

|

||||

# Wall Wetting

|

||||

|

||||

This is a more sophisticated method that was developed in the 1980s by the Ford Motor Company. It uses a simple model to estimate the amount of fuel that is dropping out of suspension and the time it takes to re-evaporate.

|

||||

This is a more accurate method but requires a little more knowledge to tune.

|

||||

This is a more accurate method but requires a little more knowledge to tune.

|

||||

|

||||

# Engine Load based

|

||||

# Engine Load based

|

||||

|

||||

[//]: # "To do by someone with more understanding of this implementation"

|

||||

|

||||

[//]: # "OrchardPerformance"

|

||||

[//]: # "OrchardPerformance"

|

||||

|

|

|

|||

|

|

@ -1,11 +1,11 @@

|

|||

# Acura RSX

|

||||

|

||||

# 2003

|

||||

|

||||

[2003-acura-rsx-type-R.pdf](https://github.com/rusefi/rusefi_documentation/raw/master/OEM-Docs/Honda/2003-acura-rsx-type-R.pdf)

|

||||

|

||||

# 2005

|

||||

|

||||

|

||||

|

||||

|

||||

|

||||

|

|

@ -17,5 +17,3 @@

|

|||

|

||||

|

||||

|

||||

|

||||

|

||||

|

|

|

|||

|

|

@ -9,4 +9,3 @@

|

|||

|

||||

|

||||

|

||||

|

||||

|

|

|

|||

|

|

@ -3,27 +3,25 @@

|

|||

[ArsTechnica: DSC Sport’s active shocks in action](https://arstechnica.com/cars/2015/07/the-future-of-car-suspension-is-here-dsc-sports-active-shocks-in-action/)

|

||||

"Normally, a car's weight transfers from front to back as it brakes and accelerates, and from side to side as it corners. As the force on each corner changes, so does the grip available to that wheel; less weight equals less grip. Active shocks control this by varying the degree to which each spring's compresses and extends (as the springs are passive, these systems are sometimes known as semi-active)."

|

||||

|

||||

|

||||

[Active Suspension - Wikipedia]](http://en.wikipedia.org/wiki/Active_suspension)

|

||||

[Active Suspension - Wikipedia]](<http://en.wikipedia.org/wiki/Active_suspension>)

|

||||

|

||||

[Active Suspension banned](http://www.f1fanatic.co.uk/2007/05/17/banned-active-suspension/)

|

||||

|

||||

[Northstar Engine Series - Wikipedia]](http://en.wikipedia.org/wiki/Northstar_engine_series)

|

||||

[Northstar Engine Series - Wikipedia]](<http://en.wikipedia.org/wiki/Northstar_engine_series>)

|

||||

Road Sensing Suspension

|

||||

RSS

|

||||

CV-RSS continuously-variable CV-RSS

|

||||

|

||||

[Magneride Applications - Wikipedia]](https://en.wikipedia.org/wiki/MagneRide#Applications)

|

||||

[Magneride Applications - Wikipedia]](<https://en.wikipedia.org/wiki/MagneRide#Applications>)

|

||||

|

||||

[Toyota Active Control Suspension - Wikipedia]](https://en.wikipedia.org/wiki/Toyota_Active_Control_Suspension)

|

||||

[Toyota Active Control Suspension - Wikipedia]](<https://en.wikipedia.org/wiki/Toyota_Active_Control_Suspension>)

|

||||

|

||||

"yaw velocity sensors, vertical G sensors, height sensors, wheel speed sensors, longitudinal and lateral G sensors) that detected cornering, acceleration and braking forces"

|

||||

|

||||

Mercedes-Benz hydraulic fully active suspension: [Active Body Control - Wikipedia]](https://en.wikipedia.org/wiki/Active_Body_Control)

|

||||

Mercedes-Benz hydraulic fully active suspension: [Active Body Control - Wikipedia]](<https://en.wikipedia.org/wiki/Active_Body_Control>)

|

||||

W220: "Prior to September 2002, only higher end models" S600 2003 "ABC system which combined an hydraulic system and springs"

|

||||

Furthermore, at highway speeds the suspension computer automatically engages sport mode (Airmatic - Sport mode 1 or 2 depending on the current speed), thus aiding safety by significantly reducing body roll in sharp turns.

|

||||

|

||||

|

||||

[broken link](http://www.drifting.com/forums/tech-discussion-forum/6741-suspension-101-stiffer-is-better-text-by-tanabe-u-s-a.html)

|

||||

|

||||

[Article tells how CVRSS works](http://www.cadillacforums.com/forums/suspension-brakes-tires/175670-article-tells-how-cvrss-works.html)

|

||||

|

|

@ -41,7 +39,7 @@ Used hardware:

|

|||

[Fe1 suspension system,soft ride soft ride susp](http://www.cadillacforums.com/forums/cadillac-seville-cadillac-eldorado-forum/212531-fe1-suspension-system-soft-ride-soft.html)

|

||||

"2000 Seville STS - 98 to 2004 F45 is CVRSS"

|

||||

|

||||

gm 22784742

|

||||

gm 22784742

|

||||

|

||||

"it has rotory sensors on the frame that connect to each lower suspension a arm. these give the rate of bump and rebound, and Rate of travel"

|

||||

|

||||

|

|

@ -53,7 +51,6 @@ yaw sensor

|

|||

|

||||

[How Magnets Make The Camaro ZL1 Dance Around A Race Track - Jalopnik](http://jalopnik.com/5932764/how-magnets-make-the-camaro-zl1-dance-around-a-race-track)

|

||||

|

||||

|

||||

[Car that can 'jump' potholes - Video](https://www.youtube.com/watch?v=DS9LjHSTofw)

|

||||

|

||||

shock connector adapter GM 19180262 [https://www.cadillacforums.com/forums/cadillac-escalade-ext-esv-forum-2007/1067118-how-delete-z95-front-rear-mrc.html](https://www.cadillacforums.com/forums/cadillac-escalade-ext-esv-forum-2007/1067118-how-delete-z95-front-rear-mrc.html)

|

||||

|

|

|

|||

23

AlphaN.md

23

AlphaN.md

|

|

@ -1,26 +1,25 @@

|

|||

# AlphaN fueling

|

||||

|

||||

AlphaN is a method of fueling that uses the angle of the TPS (Alpha) and the RPM of the engine (N) to determine how much fuel should be injected.

|

||||

AlphaN is a method of fueling that uses the angle of the TPS (Alpha) and the RPM of the engine (N) to determine how much fuel should be injected.

|

||||

|

||||

It is a very simple method that simply uses the Alpha as the Y axis and N as the X axis of the fuel table.

|

||||

It is a very simple method that simply uses the Alpha as the Y axis and N as the X axis of the fuel table.

|

||||

|

||||

This method is most commonly used on pure race cars that are willing to sacrifice an amount of drivability for simplicity, or on installations where there is a great difficulty reading for a MAP or MAF sensor.

|

||||

An example of this would be ITBs.

|

||||

This method is most commonly used on pure race cars that are willing to sacrifice an amount of drivability for simplicity, or on installations where there is a great difficulty reading for a MAP or MAF sensor.

|

||||

An example of this would be ITBs.

|

||||

|

||||

It is not suggested that this method is used with rusEFI as we have implemented very good windowing and smoothing of MAP sensor signals, which allows for the speed density method to be used reliably on systems where it would not traditionally function well.

|

||||

However we are aware that there are many users that would still prefer to use this method so it has been provided.

|

||||

However we are aware that there are many users that would still prefer to use this method so it has been provided.

|

||||

|

||||

# The detail

|

||||

# The detail

|

||||

|

||||

fuel_squirt_duration = injector_lag_curve_lookup(V_BATT) + warm_up_curve_lookup(COOLANT_TEMPERATURE) * intake_air_correction_curve_lookup(INTAKE_AIR_TEMP) * fuel_table_lookup(RPM, TPS)

|

||||

fuel_squirt_duration = injector_lag_curve_lookup(V_BATT) + warm_up_curve_lookup(COOLANT_TEMPERATURE) *intake_air_correction_curve_lookup(INTAKE_AIR_TEMP)* fuel_table_lookup(RPM, TPS)

|

||||

|

||||

Where TPS is the reading at the start of engine cycle

|

||||

|

||||

# How to tune

|

||||

# How to tune

|

||||

|

||||

The AlphaN system in rusEFI can be tuned in the same way as all other standalone ECUs, it is simply a case of inputting the required fuel values in the main fuel table.

|

||||

The AlphaN system in rusEFI can be tuned in the same way as all other standalone ECUs, it is simply a case of inputting the required fuel values in the main fuel table.

|

||||

|

||||

It is planned that a future update will modify this table to be a VE table in a similar way to several other aftermarket systems. This will be done for simplicity of use.

|

||||

It is planned that a future update will modify this table to be a VE table in a similar way to several other aftermarket systems. This will be done for simplicity of use.

|

||||

|

||||

|

||||

[//]: # "OrchardPerformance"

|

||||

[//]: # "OrchardPerformance"

|

||||

|

|

|

|||

|

|

@ -4,12 +4,10 @@

|

|||

|

||||

[Snapshot firmware bundle](https://rusefi.com/build_server/rusefi_bundle_alphax-2chan.zip)

|

||||

|

||||

|

||||

[Pinout](https://rusefi.com/docs/pinouts/hellen/alphax-2chan/)

|

||||

|

||||

[iBom rev C](https://rusefi.com/docs/ibom/alphax_2ch-c-ibom.html)

|

||||

|

||||

|

||||

[iBom rev B](https://rusefi.com/docs/ibom/alphax_2ch-b-ibom.html)

|

||||

|

||||

[Issue tracker & hardware files](https://github.com/rusefi/alphax-2chan)

|

||||

|

|

@ -22,33 +20,36 @@ On-board MPXH6400A

|

|||

|

||||

[See also AlphaX-4chan](AlphaX-4chan)

|

||||

|

||||

|

||||

## Q: how many injectors per channel?

|

||||

|

||||

A: VND14NV04TR-E 93mJ 18A. In terms of current and switching energy those could handle _many_ injectors per channel, maybe a dozen?

|

||||

|

||||

|

||||

## Changelog

|

||||

|

||||

rev E:

|

||||

December 2022

|

||||

- migrated to Hellen MegaModule 0.1

|

||||

|

||||

- migrated to Hellen MegaModule 0.1

|

||||

|

||||

rev D:

|

||||

September 2022

|

||||

- crank/cam test pads https://github.com/rusefi/alphax-2chan/issues/63

|

||||

- TSOP-10 TLS115 https://github.com/rusefi/alphax-2chan/issues/64

|

||||

|

||||

- crank/cam test pads <https://github.com/rusefi/alphax-2chan/issues/63>

|

||||

- TSOP-10 TLS115 <https://github.com/rusefi/alphax-2chan/issues/64>

|

||||

|

||||

rev C:

|

||||

- pull-down fixed https://github.com/rusefi/alphax-2chan/issues/40

|

||||

- affected by BOM issue p-channel mosfet https://github.com/rusefi/alphax-2chan/issues/53

|

||||

|

||||

- pull-down fixed <https://github.com/rusefi/alphax-2chan/issues/40>

|

||||

- affected by BOM issue p-channel mosfet <https://github.com/rusefi/alphax-2chan/issues/53>

|

||||

|

||||

rev B:

|

||||

- affected by BOM issue p-channel mosfet https://github.com/rusefi/alphax-2chan/issues/53

|

||||

* BT fixed

|

||||

|

||||

- affected by BOM issue p-channel mosfet <https://github.com/rusefi/alphax-2chan/issues/53>

|

||||

- BT fixed

|

||||

``

|

||||

bluetooth_jdy 115200 alphax 1234

|

||||

``

|

||||

|

||||

rev A:

|

||||

- affected by BOM issue p-channel mosfet https://github.com/rusefi/alphax-2chan/issues/53

|

||||

|

||||

- affected by BOM issue p-channel mosfet <https://github.com/rusefi/alphax-2chan/issues/53>

|

||||

|

|

|

|||

|

|

@ -10,12 +10,12 @@

|

|||

[iBom rev D](https://rusefi.com/docs/ibom/alphax_4ch-d-ibom.html)

|

||||

[iBom rev C](https://rusefi.com/docs/ibom/alphax_4ch-c-ibom.html)

|

||||

[iBom rev B](https://rusefi.com/docs/ibom/alphax_4ch-b-ibom.html)

|

||||

[iBom rev A](https://rusefi.com/docs/ibom/alphax_4ch-a-ibom.html)

|

||||

[iBom rev A](https://rusefi.com/docs/ibom/alphax_4ch-a-ibom.html)

|

||||

|

||||

[Issue tracker & hardware files](https://github.com/rusefi/alphax-4chan)

|

||||

|

||||

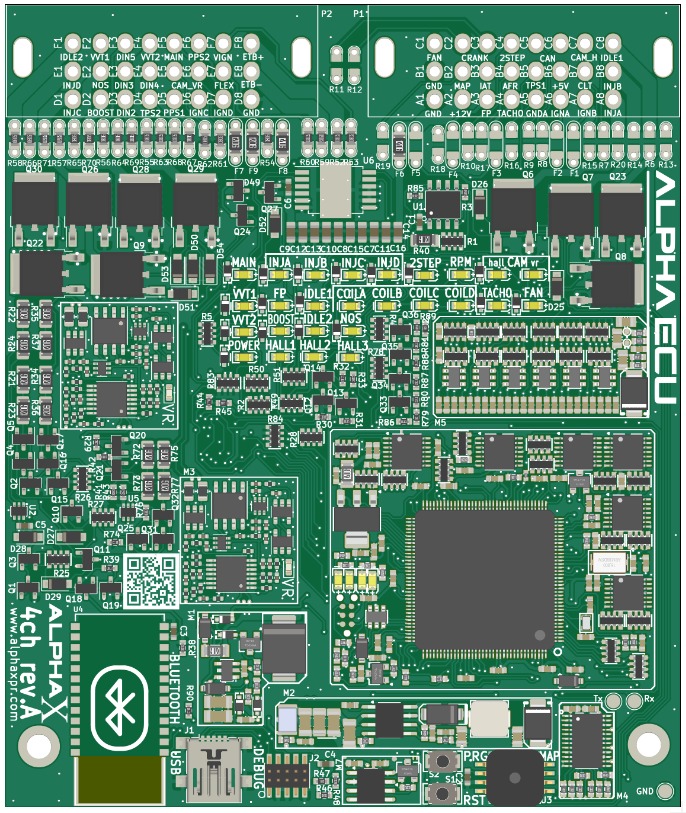

* 4 injector channels

|

||||

* 4 logic level coil control

|

||||

* 4 logic level coil control

|

||||

* 5 auxiliary low side outputs up to 5A

|

||||

* 2 VR inputs

|

||||

* 3 Hall inputs

|

||||

|

|

@ -24,25 +24,27 @@

|

|||

* one channel knock input

|

||||

* Bluetooth

|

||||

|

||||

|

||||

|

||||

|

||||

|

||||

## Changelog

|

||||

|

||||

rev D:

|

||||

- SD card added

|

||||

|

||||

* SD card added

|

||||

|

||||

rev C:

|

||||

- improved PCB shape

|

||||

- better thermal and overall simpler to solder

|

||||

- https://github.com/rusefi/alphax-4chan/issues?q=is%3Aissue+label%3AREV-C

|

||||

|

||||

* improved PCB shape

|

||||

* better thermal and overall simpler to solder

|

||||

* <https://github.com/rusefi/alphax-4chan/issues?q=is%3Aissue+label%3AREV-C>

|

||||

|

||||

rev B:

|

||||

- one channel knock input added

|

||||

- gerber defect under C461 https://github.com/rusefi/alphax-4chan/issues/20

|

||||

- BOM issue p-channel mosfet https://github.com/rusefi/alphax-4chan/issues/19

|

||||

|

||||

* one channel knock input added

|

||||

* gerber defect under C461 <https://github.com/rusefi/alphax-4chan/issues/20>

|

||||

* BOM issue p-channel mosfet <https://github.com/rusefi/alphax-4chan/issues/19>

|

||||

|

||||

rev A:

|

||||

- it works! https://youtu.be/egtDQsMDQqs

|

||||

- BOM issue p-channel mosfet https://github.com/rusefi/alphax-4chan/issues/19

|

||||

|

||||

* it works! <https://youtu.be/egtDQsMDQqs>

|

||||

* BOM issue p-channel mosfet <https://github.com/rusefi/alphax-4chan/issues/19>

|

||||

|

|

|

|||

|

|

@ -2,9 +2,6 @@

|

|||

|

||||

[Issue tracker & hardware files](https://github.com/rusefi/alphax-8chan)

|

||||

|

||||

|

||||

|

||||

|

||||

* 8 HighZ injector channels

|

||||

* 8 logic level coil control

|

||||

* 4 H-bridges

|

||||

|

|

@ -14,14 +11,11 @@

|

|||

* Dual on-board WBO controller

|

||||

* Bluetooth

|

||||

|

||||

|

||||

## Parts

|

||||

|

||||

| | TE |

|

||||

|---|---|

|

||||

|A Wire | [4-1437290-0](https://www.te.com/usa-en/product-4-1437290-0.html) |

|

||||

|B Wire | [3-1437290-7](https://www.te.com/usa-en/product-3-1437290-7.html) |

|

||||

|C Wire |[4-1437290-1](https://www.te.com/usa-en/product-4-1437290-1.html) |

|

||||

|D Wire | [3-1437290-8](https://www.te.com/usa-en/product-3-1437290-8.html) |

|

||||

|

||||

|

||||

|A Wire | [4-1437290-0](https://www.te.com/usa-en/product-4-1437290-0.html) |

|

||||

|B Wire | [3-1437290-7](https://www.te.com/usa-en/product-3-1437290-7.html) |

|

||||

|C Wire |[4-1437290-1](https://www.te.com/usa-en/product-4-1437290-1.html) |

|

||||

|D Wire | [3-1437290-8](https://www.te.com/usa-en/product-3-1437290-8.html) |

|

||||

|

|

|

|||

|

|

@ -1,4 +1,4 @@

|

|||

Based on

|

||||

Based on

|

||||

|

||||

nb2-happy-warmup-idle.csv

|

||||

|

||||

|

|

@ -6,4 +6,4 @@ nb2-idle-without-injector-2.csv

|

|||

|

||||

nb2-suspected-bad-sparkplug-1.csv

|

||||

|

||||

nb2-sparkplug-1-completely-removed-zero-compression-in-1.csv

|

||||

nb2-sparkplug-1-completely-removed-zero-compression-in-1.csv

|

||||

|

|

|

|||

|

|

@ -1 +1 @@

|

|||

Hello [https://github.com/mck1117/atlas](https://github.com/mck1117/atlas)

|

||||

Hello [https://github.com/mck1117/atlas](https://github.com/mck1117/atlas)

|

||||

|

|

|

|||

264

B6-temp.md

264

B6-temp.md

|

|

@ -22,42 +22,42 @@ MOTOR_7 = 0x588

|

|||

fakeTorque = 0

|

||||

|

||||

function xorChecksum(data, targetIndex)

|

||||

local index = 1

|

||||

local result = 0

|

||||

while data[index] ~= nil do

|

||||

if index ~= targetIndex then

|

||||

result = result ~ data[index]

|

||||

end

|

||||

index = index + 1

|

||||

end

|

||||

data[targetIndex] = result

|

||||

return result

|

||||

local index = 1

|

||||

local result = 0

|

||||

while data[index] ~= nil do

|

||||

if index ~= targetIndex then

|

||||

result = result ~ data[index]

|

||||

end

|

||||

index = index + 1

|

||||

end

|

||||

data[targetIndex] = result

|

||||

return result

|

||||

end

|

||||

|

||||

function setBitRange(data, totalBitIndex, bitWidth, value)

|

||||

local byteIndex = totalBitIndex >> 3

|

||||

local bitInByteIndex = totalBitIndex - byteIndex * 8

|

||||

if (bitInByteIndex + bitWidth > 8) then

|

||||

bitsToHandleNow = 8 - bitInByteIndex

|

||||

setBitRange(data, totalBitIndex + bitsToHandleNow, bitWidth - bitsToHandleNow, value >> bitsToHandleNow)

|

||||

bitWidth = bitsToHandleNow

|

||||

end

|

||||

mask = (1 << bitWidth) - 1

|

||||

data[1 + byteIndex] = data[1 + byteIndex] & (~(mask << bitInByteIndex))

|

||||

maskedValue = value & mask

|

||||

shiftedValue = maskedValue << bitInByteIndex

|

||||

data[1 + byteIndex] = data[1 + byteIndex] | shiftedValue

|

||||

local byteIndex = totalBitIndex >> 3

|

||||

local bitInByteIndex = totalBitIndex - byteIndex * 8

|

||||

if (bitInByteIndex + bitWidth > 8) then

|

||||

bitsToHandleNow = 8 - bitInByteIndex

|

||||

setBitRange(data, totalBitIndex + bitsToHandleNow, bitWidth - bitsToHandleNow, value >> bitsToHandleNow)

|

||||

bitWidth = bitsToHandleNow

|

||||

end

|

||||

mask = (1 << bitWidth) - 1

|

||||

data[1 + byteIndex] = data[1 + byteIndex] & (~(mask << bitInByteIndex))

|

||||

maskedValue = value & mask

|

||||

shiftedValue = maskedValue << bitInByteIndex

|

||||

data[1 + byteIndex] = data[1 + byteIndex] | shiftedValue

|

||||

end

|

||||

|

||||

function getBitRange(data, bitIndex, bitWidth)

|

||||

byteIndex = bitIndex >> 3

|

||||

shift = bitIndex - byteIndex * 8

|

||||

value = data[1 + byteIndex]

|

||||

if (shift + bitWidth > 8) then

|

||||

value = value + data[2 + byteIndex] * 256

|

||||

end

|

||||

mask = (1 << bitWidth) - 1

|

||||

return (value >> shift) & mask

|

||||

byteIndex = bitIndex >> 3

|

||||

shift = bitIndex - byteIndex * 8

|

||||

value = data[1 + byteIndex]

|

||||

if (shift + bitWidth > 8) then

|

||||

value = value + data[2 + byteIndex] * 256

|

||||

end

|

||||

mask = (1 << bitWidth) - 1

|

||||

return (value >> shift) & mask

|

||||

end

|

||||

|

||||

-- sometimes we want to cut a CAN bus and install rusEFI into that cut

|

||||

|

|

@ -71,35 +71,35 @@ ECU_BUS = 1

|

|||

TCU_BUS = 2

|

||||

|

||||

function setTwoBytes(data, offset, value)

|

||||

value = math.floor(value)

|

||||

data[offset + 2] = value >> 8

|

||||

data[offset + 1] = value & 0xff

|

||||

value = math.floor(value)

|

||||

data[offset + 2] = value >> 8

|

||||

data[offset + 1] = value & 0xff

|

||||

end

|

||||

|

||||

hexstr = { 0, 1, 2, 3, 4, 5, 6, 7, 8, 9, "A", "B", "C", "D", "E", "F" }

|

||||

|

||||

function toHexString(num)

|

||||

if num == 0 then

|

||||

return '0'

|

||||

end

|

||||

if num == 0 then

|

||||

return '0'

|

||||

end

|

||||

|

||||

local result = ""

|

||||

while num > 0 do

|

||||

local n = num % 16

|

||||

result = hexstr[n + 1] ..result

|

||||

num = math.floor(num / 16)

|

||||

end

|

||||

return result

|

||||

local result = ""

|

||||

while num > 0 do

|

||||

local n = num % 16

|

||||

result = hexstr[n + 1] ..result

|

||||

num = math.floor(num / 16)

|

||||

end

|

||||

return result

|

||||

end

|

||||

|

||||

function arrayToString(arr)

|

||||

local str = ""

|

||||

local index = 1

|

||||

while arr[index] ~= nil do

|

||||

str = str.." "..toHexString(arr[index])

|

||||

index = index + 1

|

||||

end

|

||||

return str

|

||||

local str = ""

|

||||

local index = 1

|

||||

while arr[index] ~= nil do

|

||||

str = str.." "..toHexString(arr[index])

|

||||

index = index + 1

|

||||

end

|

||||

return str

|

||||

end

|

||||

|

||||

totalEcuMessages = 0

|

||||

|

|

@ -119,50 +119,50 @@ motor7Data = { 0x1A, 0x66, 0x7E, 0x00, 0x00, 0x00, 0x00, 0x00 }

|

|||

|

||||

function onMotor1(bus, id, dlc, data)

|

||||

totalEcuMessages = totalEcuMessages + 1

|

||||

rpm = getBitRange(data, 16, 16) * 0.25

|

||||

tps = getBitRange(data, 40, 8) * 0.4

|

||||

rpm = getBitRange(data, 16, 16) * 0.25

|

||||

tps = getBitRange(data, 40, 8) * 0.4

|

||||

|

||||

fakeTorque = interpolate(0, 6, 100, 60, tps)

|

||||

fakeTorque = interpolate(0, 6, 100, 60, tps)

|

||||

|

||||

-- engineTorque = getBitRange(data, 8, 8) * 0.39

|

||||

-- innerTorqWithoutExt = getBitRange(data, 32, 8) * 0.4

|

||||

-- torqueLoss = getBitRange(data, 48, 8) * 0.39

|

||||

-- requestedTorque = getBitRange(data, 56, 8) * 0.39

|

||||

-- engineTorque = getBitRange(data, 8, 8) * 0.39

|

||||

-- innerTorqWithoutExt = getBitRange(data, 32, 8) * 0.4

|

||||

-- torqueLoss = getBitRange(data, 48, 8) * 0.39

|

||||

-- requestedTorque = getBitRange(data, 56, 8) * 0.39

|

||||

|

||||

engineTorque = fakeTorque * 0.9

|

||||

innerTorqWithoutExt = fakeTorque

|

||||

torqueLoss = 20

|

||||

requestedTorque = fakeTorque

|

||||

engineTorque = fakeTorque * 0.9

|

||||

innerTorqWithoutExt = fakeTorque

|

||||

torqueLoss = 20

|

||||

requestedTorque = fakeTorque

|

||||

|

||||

motor1Data[2] = engineTorque / 0.39

|

||||

setTwoBytes(motor1Data, 2, rpm / 0.25)

|

||||

motor1Data[5] = innerTorqWithoutExt / 0.4

|

||||

motor1Data[6] = tps / 0.4

|

||||

motor1Data[7] = torqueLoss / 0.39

|

||||

motor1Data[8] = requestedTorque / 0.39

|

||||

motor1Data[2] = engineTorque / 0.39

|

||||

setTwoBytes(motor1Data, 2, rpm / 0.25)

|

||||

motor1Data[5] = innerTorqWithoutExt / 0.4

|

||||

motor1Data[6] = tps / 0.4

|

||||

motor1Data[7] = torqueLoss / 0.39

|

||||

motor1Data[8] = requestedTorque / 0.39

|

||||

|

||||

-- print ('MOTOR_1 fakeTorque ' ..fakeTorque)

|

||||

-- print ('MOTOR_1 engineTorque ' ..engineTorque ..' RPM ' ..rpm)

|

||||

-- print ('MOTOR_1 innerTorqWithoutExt ' ..innerTorqWithoutExt ..' tps ' ..tps)

|

||||

-- print ('MOTOR_1 fakeTorque ' ..fakeTorque)

|

||||

-- print ('MOTOR_1 engineTorque ' ..engineTorque ..' RPM ' ..rpm)

|

||||

-- print ('MOTOR_1 innerTorqWithoutExt ' ..innerTorqWithoutExt ..' tps ' ..tps)

|

||||

|

||||

-- print ('MOTOR_1 torqueLoss ' ..torqueLoss ..' requestedTorque ' ..requestedTorque)

|

||||

-- print ('MOTOR_1 torqueLoss ' ..torqueLoss ..' requestedTorque ' ..requestedTorque)

|

||||

|

||||

txCan(TCU_BUS, id, 0, motor1Data)

|

||||

txCan(TCU_BUS, id, 0, motor1Data)

|

||||

end

|

||||

|

||||

motorBreCounter = 0

|

||||

function onMotorBre(bus, id, dlc, data)

|

||||

motorBreCounter = (motorBreCounter + 1) % 16

|

||||

motorBreCounter = (motorBreCounter + 1) % 16

|

||||

|

||||

setBitRange(motorBreData, 8, 4, motorBreCounter)

|

||||

xorChecksum(motorBreData, 1)

|

||||

|

||||

txCan(TCU_BUS, id, 0, motorBreData)

|

||||

txCan(TCU_BUS, id, 0, motorBreData)

|

||||

end

|

||||

|

||||

motor2counter = 0

|

||||

function onMotor2(bus, id, dlc, data)

|

||||

motor2counter = (motor2counter + 1) % 16

|

||||

motor2counter = (motor2counter + 1) % 16

|

||||

|

||||

minTorque = fakeTorque / 2

|

||||

motor2Data[7] = math.floor(minTorque / 0.39)

|

||||

|

|

@ -175,86 +175,86 @@ function onMotor2(bus, id, dlc, data)

|

|||

index = math.floor(motor2counter / 4)

|

||||

motor2Data[1] = motor2mux[1 + index]

|

||||

|

||||

-- txCan(TCU_BUS, id, 0, data)

|

||||

txCan(TCU_BUS, id, 0, motor2Data)

|

||||

-- txCan(TCU_BUS, id, 0, data)

|

||||

txCan(TCU_BUS, id, 0, motor2Data)

|

||||

end

|

||||

|

||||

function onMotor3(bus, id, dlc, data)

|

||||

totalEcuMessages = totalEcuMessages + 1

|

||||

iat = getBitRange(data, 8, 8) * 0.75 - 48

|

||||

pps = getBitRange(data, 16, 8) * 0.40

|

||||

tps = getBitRange(data, 56, 8) * 0.40

|

||||

-- print ('MOTOR_1 pps ' ..pps ..' tps ' ..tps ..' iat ' ..iat)

|

||||

iat = getBitRange(data, 8, 8) * 0.75 - 48

|

||||

pps = getBitRange(data, 16, 8) * 0.40

|

||||

tps = getBitRange(data, 56, 8) * 0.40

|

||||

-- print ('MOTOR_1 pps ' ..pps ..' tps ' ..tps ..' iat ' ..iat)

|

||||

|

||||

|

||||

desired_wheel_torque = fakeTorque

|

||||

canMotor3[2] = (iat + 48) / 0.75

|

||||

canMotor3[3] = tps / 0.4

|

||||

canMotor3[5] = 0x20

|

||||

setBitRange(canMotor3, 24, 12, math.floor(desired_wheel_torque / 0.39))

|

||||

canMotor3[8] = tps / 0.4

|

||||

txCan(TCU_BUS, id, 0, canMotor3)

|

||||

desired_wheel_torque = fakeTorque

|

||||

canMotor3[2] = (iat + 48) / 0.75

|

||||

canMotor3[3] = tps / 0.4

|

||||

canMotor3[5] = 0x20

|

||||

setBitRange(canMotor3, 24, 12, math.floor(desired_wheel_torque / 0.39))

|

||||

canMotor3[8] = tps / 0.4

|

||||

txCan(TCU_BUS, id, 0, canMotor3)

|

||||

end

|

||||

|

||||

motor5FuelCounter = 0

|

||||

function onMotor5(bus, id, dlc, data)

|

||||

setBitRange(motor5Data, 5, 9, motor5FuelCounter)

|

||||

xorChecksum(motor5Data, 8)

|

||||

txCan(TCU_BUS, id, 0, motor5Data)

|

||||

setBitRange(motor5Data, 5, 9, motor5FuelCounter)

|

||||

xorChecksum(motor5Data, 8)

|

||||

txCan(TCU_BUS, id, 0, motor5Data)

|

||||

end

|

||||

|

||||

counter16 = 0

|

||||

function onMotor6(bus, id, dlc, data)

|

||||

counter16 = (counter16 + 1) % 16

|

||||

counter16 = (counter16 + 1) % 16

|

||||

|

||||

-- engineTorque = getBitRange(data, 8, 8) * 0.39

|

||||

-- actualTorque = getBitRange(data, 16, 8) * 0.39

|

||||

-- feedbackGearbox = getBitRange(data, 40, 8) * 0.39

|

||||

engineTorque = fakeTorque * 0.9

|

||||

actualTorque = fakeTorque

|

||||

feedbackGearbox = 255

|

||||

-- engineTorque = getBitRange(data, 8, 8) * 0.39

|

||||

-- actualTorque = getBitRange(data, 16, 8) * 0.39

|

||||

-- feedbackGearbox = getBitRange(data, 40, 8) * 0.39

|

||||

engineTorque = fakeTorque * 0.9

|

||||

actualTorque = fakeTorque

|

||||

feedbackGearbox = 255

|

||||

|

||||

motor6Data[2] = math.floor(engineTorque / 0.39)

|

||||

motor6Data[3] = math.floor(actualTorque / 0.39)

|

||||

motor6Data[6] = math.floor(feedbackGearbox / 0.39)

|

||||

setBitRange(motor6Data, 60, 4, counter16)

|

||||

motor6Data[2] = math.floor(engineTorque / 0.39)

|

||||

motor6Data[3] = math.floor(actualTorque / 0.39)

|

||||

motor6Data[6] = math.floor(feedbackGearbox / 0.39)

|

||||

setBitRange(motor6Data, 60, 4, counter16)

|

||||

|

||||

xorChecksum(motor6Data, 1)

|

||||

txCan(TCU_BUS, id, 0, motor6Data)

|

||||

xorChecksum(motor6Data, 1)

|

||||

txCan(TCU_BUS, id, 0, motor6Data)

|

||||

end

|

||||

|

||||

accGraCounter = 0

|

||||

function onAccGra(bus, id, dlc, data)

|

||||

accGraCounter = (accGraCounter + 1) % 16

|

||||

setBitRange(accGraData, 60, 4, accGraCounter)

|

||||

accGraCounter = (accGraCounter + 1) % 16

|

||||

setBitRange(accGraData, 60, 4, accGraCounter)

|

||||

xorChecksum(accGraData, 1)

|

||||

|

||||

txCan(TCU_BUS, id, 0, accGraData)

|

||||

-- txCan(TCU_BUS, id, 0, data)

|

||||

txCan(TCU_BUS, id, 0, accGraData)

|

||||

-- txCan(TCU_BUS, id, 0, data)

|

||||

end

|

||||

|

||||

canMotorInfoCounter = 0

|

||||

function onMotorInfo(bus, id, dlc, data)

|

||||

canMotorInfoCounter = (canMotorInfoCounter + 1) % 16

|

||||

canMotorInfo[1] = 0x80 + (canMotorInfoCounter)

|

||||

canMotorInfo1[1] = 0x80 + (canMotorInfoCounter)

|

||||

canMotorInfo3[1] = 0x80 + (canMotorInfoCounter)

|

||||

mod4 = canMotorInfoCounter % 4

|

||||

|

||||

|

||||

if (mod4 == 0 or mod4 == 2) then

|

||||

-- txCan(1, MOTOR_INFO, 0, canMotorInfo)

|

||||

txCan(TCU_BUS, id, 0, data)

|

||||

elseif (mod4 == 1) then

|

||||

txCan(1, MOTOR_INFO, 0, canMotorInfo1)

|

||||

else

|

||||

txCan(1, MOTOR_INFO, 0, canMotorInfo3)

|

||||

canMotorInfoCounter = (canMotorInfoCounter + 1) % 16

|

||||

canMotorInfo[1] = 0x80 + (canMotorInfoCounter)

|

||||

canMotorInfo1[1] = 0x80 + (canMotorInfoCounter)

|

||||

canMotorInfo3[1] = 0x80 + (canMotorInfoCounter)

|

||||

mod4 = canMotorInfoCounter % 4

|

||||

|

||||

|

||||

if (mod4 == 0 or mod4 == 2) then

|

||||

-- txCan(1, MOTOR_INFO, 0, canMotorInfo)

|

||||

txCan(TCU_BUS, id, 0, data)

|

||||

elseif (mod4 == 1) then

|

||||

txCan(1, MOTOR_INFO, 0, canMotorInfo1)

|

||||

else

|

||||

txCan(1, MOTOR_INFO, 0, canMotorInfo3)

|

||||

end

|

||||

end

|

||||

|

||||

function onMotor7(bus, id, dlc, data)

|

||||

txCan(TCU_BUS, id, 0, motor7Data)

|

||||

-- txCan(TCU_BUS, id, 0, data)

|

||||

txCan(TCU_BUS, id, 0, motor7Data)

|

||||

-- txCan(TCU_BUS, id, 0, data)

|

||||

end

|

||||

|

||||

canRxAdd(ECU_BUS, MOTOR_1, onMotor1)

|

||||

|

|

@ -275,15 +275,15 @@ mafCalibrationIndex = findCurveIndex("mafcurve")

|

|||

|

||||

function onTick()

|

||||

freqValue = getSensor("AuxSpeed1") or 0

|

||||

mafValue = curve(mafCalibrationIndex, 5)

|

||||

-- print(freqValue .. " mafValue=" .. mafValue)

|

||||

mafSensor : set(mafValue)

|

||||

mafValue = curve(mafCalibrationIndex, 5)

|

||||

-- print(freqValue .. " mafValue=" .. mafValue)

|

||||

mafSensor : set(mafValue)

|

||||

|

||||

if everySecondTimer : getElapsedSeconds() > 1 then

|

||||

everySecondTimer : reset()

|

||||

print("Total from ECU " ..totalEcuMessages)

|

||||

motor5FuelCounter = motor5FuelCounter + 20

|

||||

end

|

||||

if everySecondTimer : getElapsedSeconds() > 1 then

|

||||

everySecondTimer : reset()

|

||||

print("Total from ECU " ..totalEcuMessages)

|

||||

motor5FuelCounter = motor5FuelCounter + 20

|

||||

end

|

||||

end

|

||||

|

||||

|

||||

|

|

|

|||

18

BMW-N73.md

18

BMW-N73.md

|

|

@ -26,7 +26,7 @@ x2 HDEV fuel injection module 7506280 [121 pin connector](OEM-connectors#121)

|

|||

|

||||

|

||||

|

||||

# HDEV

|

||||

# HDEV

|

||||

|

||||

Injector #1 + #118

|

||||

|

||||

|

|

@ -37,11 +37,11 @@ These pins are pulled-up to +12v - low-side driven control.

|

|||

|

||||

GND #1 #2

|

||||

|

||||

Power +12v: #4 #51

|

||||

Power +12v: #4 #51

|

||||

|

||||

The larger chip inside 7506280 says 30429, obviously google knows nothing about this 30429. But it's probably CJ830.

|

||||

|

||||

SAK-C505

|

||||

SAK-C505

|

||||

|

||||

[wikipedia](https://en.wikipedia.org/wiki/BMW_7_Series_(E65))

|

||||

|

||||

|

|

@ -50,19 +50,19 @@ R=2.1OHm

|

|||

|

||||

Ignition COP 12138657273 is shared with a lot of other BMW and Mini models.

|

||||

|

||||

|

||||

CAS 61326943828 51210030982

|

||||

CAS 61356972681

|

||||

CAS 61356972681

|

||||

CAS 61326922329

|

||||

|

||||

Programming keywords:

|

||||

ISTA ICON

|

||||

|

||||

# Starting

|

||||

|

||||

|

||||

|

||||

|

||||

# Data Lines

|

||||

|

||||

|

||||

|

||||

|

||||

|

|

@ -70,7 +70,7 @@ ISTA ICON

|

|||

|

||||

|

||||

# Anti Theft

|

||||

|

||||

|

||||

|

||||

|

||||

|

||||

|

||||

|

||||

|

|

|

|||

|

|

@ -1,15 +1,19 @@

|

|||

# BMW-S1000RR

|

||||

|

||||

## Intro

|

||||

|

||||

The [BMW S1000RR Motorcycle](https://en.wikipedia.org/wiki/BMW_S1000RR#:~:text=BMW%20S1000RR%20is%20a%20race,engine%20redlined%20at%2014%2C200%20rpm.) was originally released in 2009. It is a 999cc four cylinder engine making 180-200hp depending on the model year. There have been a few changes over the years, but the general architecture remains the same.

|

||||

|

||||

## Overview

|

||||

|

||||

Model years vary in their engine configuration somewhat:

|

||||

|

||||

* 2009-2014 models used virtually the same engine, sensors, etc.

|

||||

* 2015-2018 had some minor engine updates, put out a little more power.

|

||||

* 2019 had entirely new engine that is more compact and has dual camshaft profiles that can be switched (similar to Honda VTEC).

|

||||

|

||||

2009-2018 Engine Configuration

|

||||

|

||||

* 999cc four cylinder engine with 4 valves per cylinder

|

||||

* 4x individual smart coil on plug ignition

|

||||

* 8x injectors with one set at the ports, one set in the airbox firing into the trumpets

|

||||

|

|

@ -28,4 +32,3 @@ Model years vary in their engine configuration somewhat:

|

|||

### Ignition Coils

|

||||

|

||||

### Quickshift Sensor

|

||||

|

||||

|

|

|

|||

|

|

@ -1,4 +1,4 @@

|

|||

#94 525

|

||||

# 94 525

|

||||

|

||||

|

||||

|

||||

|

|

@ -17,5 +17,3 @@

|

|||

|

||||

|

||||

|

||||

|

||||

|

||||

|

|

|

|||

|

|

@ -1,5 +1,5 @@

|

|||

#94 325

|

||||

# 94 325

|

||||

|

||||

|

||||

|

||||

|

||||

|

||||

|

|

|

|||

|

|

@ -8,5 +8,3 @@

|

|||

|

||||

|

||||

|

||||

|

||||

|

||||

|

|

|

|||

|

|

@ -27,13 +27,12 @@ ECU#5

|

|||

|

||||

|

||||

# EML

|

||||

|

||||

|

||||

|

||||

|

||||

|

||||

|

||||

|

||||

# TCU

|

||||

# TCU

|

||||

|

||||

|

||||

|

||||

|

|

@ -45,13 +44,10 @@ Shift Interlock

|

|||

Charging

|

||||

|

||||

|

||||

|

||||

|

||||

Starter

|

||||

|

||||

|

||||

Washer

|

||||

|

||||

|

||||

|

||||

[Vin Registry](http://www.e38registry.org/e38-production-numbers/)

|

||||

|

|

|

|||

|

|

@ -3,5 +3,3 @@

|

|||

* 61.35-8 378 631 "General Body Control"

|

||||

* 1 095 326 Acceleration Sensor Module: interesting, is this analog output or CAN?!

|

||||

* 0130002830 little cooling blower: only three wires? Is this engine control unit cooling system?!

|

||||

|

||||

|

||||

|

|

|

|||

12

BMW-e38.md

12

BMW-e38.md

|

|

@ -1,4 +1,4 @@

|

|||

[BMW 7 Series (E38) - Wikipedia]](https://en.wikipedia.org/wiki/BMW_7_Series_(E38))

|

||||

[BMW 7 Series (E38) - Wikipedia]](<https://en.wikipedia.org/wiki/BMW_7_Series_(E38>))

|

||||

|

||||

# 2000 740

|

||||

|

||||

|

|

@ -8,18 +8,16 @@

|

|||

|

||||

|

||||

|

||||

|

||||

| Connector/ Pin Number | OEM Color | Name / Function |

|

||||

| Connector/ Pin Number | OEM Color | Name / Function |

|

||||

| --------------------- |------- |---------------- |

|

||||

| 4 | BRN | GND Ground |

|

||||

| 5 | BRN | GND Ground |

|

||||

| 6 | BRN | GND Ground |

|

||||

| 7 | RED | +12v Hot all times |

|

||||

| 8 | RED/BLU | +12v Hot all times |

|

||||

| 7 | RED | +12v Hot all times |

|

||||

| 8 | RED/BLU | +12v Hot all times |

|

||||

| | | |

|

||||

|

||||

|

||||

| Connector/ Pin Number | OEM Color | Name / Function |

|

||||

| Connector/ Pin Number | OEM Color | Name / Function |

|

||||

| --------------------- |------- |---------------- |

|

||||

| 1 | BRN/YEL | |

|

||||

| 2 | BRN/GRN | |

|

||||

|

|

|

|||

28

BMW-e39.md

28

BMW-e39.md

|

|

@ -1,6 +1,5 @@

|

|||

|

||||

|

||||

[BMW 5 Series (E39) - Wikipedia]](https://en.wikipedia.org/wiki/BMW_5_Series_(E39))

|

||||

[BMW 5 Series (E39) - Wikipedia]](<https://en.wikipedia.org/wiki/BMW_5_Series_(E39>))

|

||||

|

||||

# 1999 528

|

||||

|

||||

|

|

@ -10,30 +9,26 @@

|

|||

|

||||

|

||||

|

||||

|

||||

| Connector/ Pin Number | OEM Color | Name / Function |

|

||||

| Connector/ Pin Number | OEM Color | Name / Function |

|

||||

| --------------------- |------- |---------------- |

|

||||

| 1 | GRN | Relay |

|

||||

| 4 | BRN | GND Ground |

|

||||

| 5 | BRN | GND Ground |

|

||||

| 6 | BRN | GND Ground |

|

||||

| 7 | RED | +12v Hot all times |

|

||||

| 8 | RED/BLU | +12v Hot all times |

|

||||

| 7 | RED | +12v Hot all times |

|

||||

| 8 | RED/BLU | +12v Hot all times |

|

||||

| | | |

|

||||

|

||||

|

||||

|

||||

| Connector/ Pin Number | OEM Color | Name / Function |

|

||||

| Connector/ Pin Number | OEM Color | Name / Function |

|

||||

| --------------------- |------- |---------------- |

|

||||

| 1 | YEL | |

|

||||

| 2 | YEL | |

|

||||

| | | |

|

||||

| | | |

|

||||

|

||||

|

||||

# 2001 540

|

||||

|

||||

[BMW M62 - Wikipedia]](https://en.wikipedia.org/wiki/BMW_M62)

|

||||

[BMW M62 - Wikipedia]](<https://en.wikipedia.org/wiki/BMW_M62>)

|

||||

|

||||

|

||||

|

||||

|

|

@ -43,19 +38,16 @@

|

|||

|

||||

|

||||

|

||||

| Connector/ Pin Number | OEM Color | Name / Function |

|

||||

| Connector/ Pin Number | OEM Color | Name / Function |

|

||||

| --------------------- |------- |---------------- |

|

||||

| 4 | BRN | GND Ground |

|

||||

| 5 | BRN | GND Ground |

|

||||

| 6 | BRN | GND Ground |

|

||||

| 7 | RED | +12v Hot all times |

|

||||

| 8 | RED/BLU | +12v Hot all times |

|

||||

| 7 | RED | +12v Hot all times |

|

||||

| 8 | RED/BLU | +12v Hot all times |

|

||||

| | | |

|

||||

|

||||

|

||||

|

||||

|

||||

| Connector/ Pin Number | OEM Color | Name / Function |

|

||||

| Connector/ Pin Number | OEM Color | Name / Function |

|

||||

| --------------------- |------- |---------------- |

|

||||

| 5 | BRN | GND Ground |

|

||||

| | | |

|

||||

|

|

|

|||

|

|

@ -11,6 +11,7 @@

|

|||

|

||||

|

||||

# M3

|

||||

|

||||

## 2002 M3

|

||||

|

||||

|

||||

|

|

@ -37,16 +38,13 @@

|

|||

|

||||

|

||||

|

||||

|

||||

|

||||

| Connector/ Pin Number | OEM Color | Name / Function |

|

||||

| Connector/ Pin Number | OEM Color | Name / Function |

|

||||

| --------------------- |------- |---------------- |

|

||||

| 5 | BRN | GND Ground |

|

||||

| 6 | BRN | GND Ground |

|

||||

| 7 | RED | +12v Hot all times |

|

||||

| 7 | RED | +12v Hot all times |

|

||||

| | | |

|

||||

|

||||

|

||||

# Trunk

|

||||

|

||||

|

||||

|

|

@ -56,4 +54,3 @@

|

|||

|

||||

|

||||

|

||||

|

||||

|

|

|

|||

|

|

@ -10,7 +10,6 @@

|

|||

|

||||

|

||||

|

||||

|

||||

# 2001 x5 4.4

|

||||

|

||||

|

||||

|

|

@ -20,4 +19,3 @@

|

|||

|

||||

|

||||

|

||||

|

||||

|

|

|

|||

16

BMW-e65.md

16

BMW-e65.md

|

|

@ -12,18 +12,16 @@ Production 2001 – 2008

|

|||

|

||||

|

||||

|

||||

|

||||

| Connector/ Pin Number | OEM Color | Name / Function |

|

||||

| Connector/ Pin Number | OEM Color | Name / Function |

|

||||

| --------------------- |------- |---------------- |

|

||||

| 3 | GRY | TCU |

|

||||

| 4 | BRN | GND Ground |

|

||||

| 6 | BRN | GND Ground |

|

||||

| 7 | RED | +12v Hot all times |

|

||||

| 8 | ORG | +12v Hot all times |

|

||||

| 7 | RED | +12v Hot all times |

|

||||

| 8 | ORG | +12v Hot all times |

|

||||

| | | |

|

||||

|

||||

|

||||

| Connector/ Pin Number | OEM Color | Name / Function |

|

||||

| Connector/ Pin Number | OEM Color | Name / Function |

|

||||

| --------------------- |------- |---------------- |

|

||||

| 2 | YEL | |

|

||||

| 3 | YEL/RED | |

|

||||

|

|

@ -31,6 +29,7 @@ Production 2001 – 2008

|

|||

| | | |

|

||||

| | | |

|

||||

| | | |

|

||||

|

||||

# 760 12 cylinders

|

||||

|

||||

See [BMW-N73](BMW-N73)

|

||||

|

|

@ -39,7 +38,7 @@ See [BMW-N73](BMW-N73)

|

|||

|

||||

[Console removal](https://www.youtube.com/watch?v=pGAeodWa_i4)

|

||||

|

||||

SRS module controls fuel pump

|

||||

SRS module controls fuel pump

|

||||

[broken link](https://lacarpro.com/blogs/dal-works/2002-1-2-bmw-745i-no-start)

|

||||

|

||||

[RHD instrument cluster removal](https://www.youtube.com/watch?v=GyVhkNa3010)

|

||||

|

|

@ -52,11 +51,8 @@ SRS module controls fuel pump

|

|||

|

||||

[User Manual](OEM-Docs/Bmw/2003_7_Series_e65/2004_Manual_7_Series.pdf)

|

||||

|

||||

|

||||

|

||||

# Transmission

|

||||

|

||||

[6 Speed Transmission mechatronic sleeve replacement](OEM-Docs/Bmw/2003_7_Series_e65/6_speed_sleeve_replacement.pdf)

|

||||

|

||||

[ZF6HP26 / 6R60 / 09E Remove Mechatronic Case Connector Sleeve Valve Body](https://www.youtube.com/watch?v=b0vvqtso14k)

|

||||

|

||||

|

|

|

|||

|

|

@ -1,3 +1,3 @@

|

|||

"Does this come with a base map?"

|

||||

|

||||

We are of the opinion that basemaps are only useful to help you load your project on a trailer in order to get to your tuning shop. In this regard more or less any map would get your project vehicle on the trailer :)

|

||||

We are of the opinion that basemaps are only useful to help you load your project on a trailer in order to get to your tuning shop. In this regard more or less any map would get your project vehicle on the trailer :)

|

||||

|

|

|

|||

|

|

@ -4,4 +4,4 @@ We use Fused deposition modeling with ABS 4% glass fiber plastic.

|

|||

|

||||

Need a box we do not have in stock? Please let me know.

|

||||

|

||||

Need a breakout we do not have in stock? Please let me know.

|

||||

Need a breakout we do not have in stock? Please let me know.

|

||||

|

|

|

|||

|

|

@ -5,47 +5,50 @@ This page is a general guide and general outline of how to use the breakout modu

|

|||

|

||||

|

||||

## Move a engine control to rusEFI

|

||||

Uses breakout module noted [here](http://rusefi.com/forum/viewtopic.php?f=4&t=454) This is an example of how you might move the wires, it may not work for you exactly this way, but this at least lays out the general process. For example, some setups connect all fuel channels to one ECU fuel channel. So you might need to do thing differently when trying to move one fuel channel as noted below. Items like that can vary.

|

||||

|

||||

Uses breakout module noted [here](http://rusefi.com/forum/viewtopic.php?f=4&t=454) This is an example of how you might move the wires, it may not work for you exactly this way, but this at least lays out the general process. For example, some setups connect all fuel channels to one ECU fuel channel. So you might need to do thing differently when trying to move one fuel channel as noted below. Items like that can vary.

|

||||

|

||||

### Capture RPM signal

|

||||

|

||||

* Cut OEM harness for the crank angle wire(s), put the leads to the breakout module, use the fuse to simple pass the signal through the breakout module, and verify that the OEM engine is operational.

|

||||

* Cut OEM harness for the crank angle wire(s), put the leads to the breakout module, use the fuse to simple pass the signal through the breakout module, and verify that the OEM engine is operational.

|

||||

* Connect rusEFI cam and/or crank to breakout module.

|

||||

* Install 2nd fuse to connect both OEM control unit and rusEFI. Take note that VR signals may be loaded and may be problematic at low RPM with this approach. Or it may simply work. Give it a try and see what happens. If it doesn't start with both connected, try starting the engine with rusEFI jumper removed, then after started install rusEFI jumper.

|

||||

* Install 2nd fuse to connect both OEM control unit and rusEFI. Take note that VR signals may be loaded and may be problematic at low RPM with this approach. Or it may simply work. Give it a try and see what happens. If it doesn't start with both connected, try starting the engine with rusEFI jumper removed, then after started install rusEFI jumper.

|

||||

* Capture crank signals via [dev console](Console.md).

|

||||

* Either configure rusEFI to use the proper crank decoder, or get a decoder developed from the dev console logs, then configure rusEFI to use the proper decoder.

|

||||

* Either configure rusEFI to use the proper crank decoder, or get a decoder developed from the dev console logs, then configure rusEFI to use the proper decoder.

|

||||

* See reliable RPM values displayed on the gauge, and noise free crank signals.

|

||||

|

||||

|

||||

|

||||

### Capture MAP or MAF signal

|

||||

|

||||

* Cut OEM harness for the MAP or MAF wire(s), or install a MAP sensor, then put the leads to the breakout module, use the fuse to simple pass the signal through the breakout module, and verify that the OEM engine is operational.

|

||||

* Cut OEM harness for the MAP or MAF wire(s), or install a MAP sensor, then put the leads to the breakout module, use the fuse to simple pass the signal through the breakout module, and verify that the OEM engine is operational.

|

||||

* Connect rusEFI analog signal to breakout module.

|

||||

* Install 2nd fuse to connect both OEM control unit and rusEFI. Take note that the signal may be loaded and may be problematic with this appraoch. Or it may simply work. Give it a try and see what happens.

|

||||

* Install 2nd fuse to connect both OEM control unit and rusEFI. Take note that the signal may be loaded and may be problematic with this appraoch. Or it may simply work. Give it a try and see what happens.

|

||||

* Capture MAF or MAP signals via dev console.

|

||||

* See reliable MAF or MAP values displayed on the gauge, and noise free signals.

|

||||

|

||||

### Move one fuel channel

|

||||

|

||||

* Cut OEM harness for one fuel channel and connect it to the breakout module. With OEM connections, verify the breakout module operates as expected on the OEM setup.

|

||||

* Cut OEM harness for one fuel channel and connect it to the breakout module. With OEM connections, verify the breakout module operates as expected on the OEM setup.

|

||||

* Connect rusEFI fuel channel to breakout module.

|

||||

* Remove fuse for OEM fuel channel and put it on rusEFI fuel channel. This can be done with running engine, but keep in mind no fuel means no power on that cyl, it will run a bit rough.

|

||||

* Connect via tuner studio, and tune your fuel channel until the engine runs smoothly. (You may be able to connect the rusEFI analog signals to the fuel channels and measure that you are generating the same fuel pulse.)

|

||||

* Continue until you have fuel control for one channel that matches perfectly for the entire RPM, loads, ect.

|

||||

* Connect via tuner studio, and tune your fuel channel until the engine runs smoothly. (You may be able to connect the rusEFI analog signals to the fuel channels and measure that you are generating the same fuel pulse.)

|

||||

* Continue until you have fuel control for one channel that matches perfectly for the entire RPM, loads, ect.

|

||||

|

||||

### Move one ignition channel

|

||||

|

||||

* Cut OEM harness for one ignition channel and connect it to the breakout module. With OEM connections, verify the breakout module operates as expected on the OEM setup. Beware, ignition signals on the primary side of the coil can get in excess of 500V, you need to capture signal level signals, not the primary side of the coil. The coil primary will destroy the discovery. The discovery board needs an igntor to drive the primary side of the coil.

|

||||

* Cut OEM harness for one ignition channel and connect it to the breakout module. With OEM connections, verify the breakout module operates as expected on the OEM setup. Beware, ignition signals on the primary side of the coil can get in excess of 500V, you need to capture signal level signals, not the primary side of the coil. The coil primary will destroy the discovery. The discovery board needs an igntor to drive the primary side of the coil.

|

||||

* Connect rusEFI ignition channel to breakout module.

|

||||

* Remove fuse for OEM fuel channel and put it on rusEFI fuel channel. This should be done when the engine is off. Moving this wire when operational will likely damage the ignition system.

|

||||

* Connect via tuner studio, and tune your ignition channel until the engine runs smoothly. (You may be able to connect the rusEFI analog signals to the channels and measure that you are generating the same fuel pulse.)

|

||||

* Continue until you have fuel control for one channel that matches perfectly for the entire RPM, loads, ect.

|

||||

* Connect via tuner studio, and tune your ignition channel until the engine runs smoothly. (You may be able to connect the rusEFI analog signals to the channels and measure that you are generating the same fuel pulse.)

|

||||

* Continue until you have fuel control for one channel that matches perfectly for the entire RPM, loads, ect.

|

||||

|

||||

### Move all fuel and ignition

|

||||

|

||||

* Cut and move fuel channels one at a time moving them to rusEFI via break out module.

|

||||

* Cut and move ignition channels one at at time moving them to rusEFI via breakout module.

|

||||

* Remove MAP and crank signals from OEM controller.

|

||||

* Cut and move ignition channels one at at time moving them to rusEFI via breakout module.

|

||||

* Remove MAP and crank signals from OEM controller.

|

||||

|

||||

### Have a rusEFI party

|

||||

* Party time as you now have rusEFI, save this OEM tune and feel free to share the tune for other developers and other project to reference.

|

||||

|

||||

* Party time as you now have rusEFI, save this OEM tune and feel free to share the tune for other developers and other project to reference.

|

||||

|

|

|

|||

|

|

@ -19,7 +19,7 @@ We have tried to keep Jenkins working in case we need to revert to it.

|

|||

|

||||

## Jenkins setup

|

||||

|

||||

### Jobs:

|

||||

### Jobs

|

||||

|

||||

1) unit_tests

|